Now that we have finished running for this year we have been able to take stock and produce the following statistics for the season for the period between our first trip to Berwyn on Friday 9th July and the last passenger service on Sunday 7th November:-

It's been a busy few months but now it's time to tackle maintenance and repairs to get things ready for the next season which looks as though it will be another busy one.

Shortly after we finish running each year we 'winterise' the fleet by draining the toilet tanks and making sure that the engines have the required concentration of anti-freeze. The anti-freeze checks were carried out last weekend...

and the required top-ups will be done when we receive more anti-freeze.

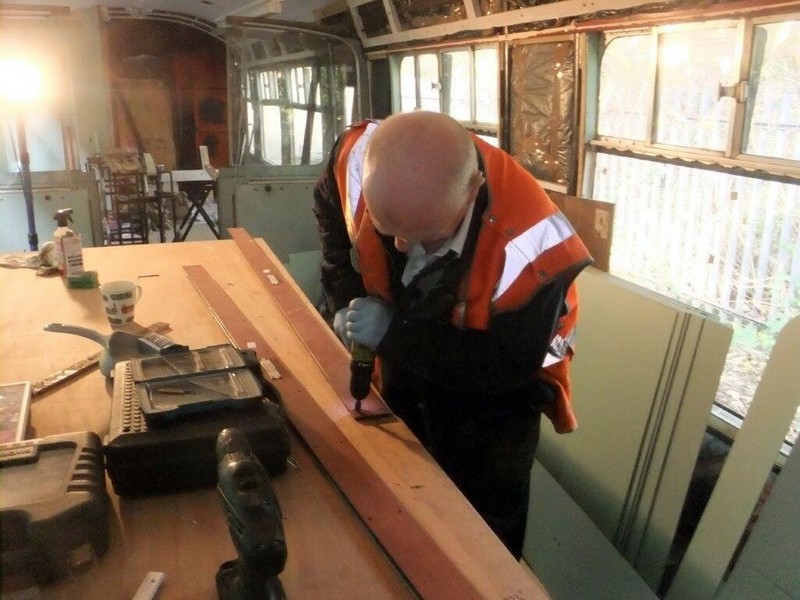

The luggage rack that had been fitted on the secondman's side of the first class section was removed and the required holes were then drilled in the panels that had been previously cut...

Some additional framework was constructed and installed to allow access to the passenger communication (passcom) securing point as well as ensuring that there was enough wood showing for the passcom lid to fasten to...

With the panels in place the finishing touches were made to the trim above the windows...

Wickham Class 109 50416/56171

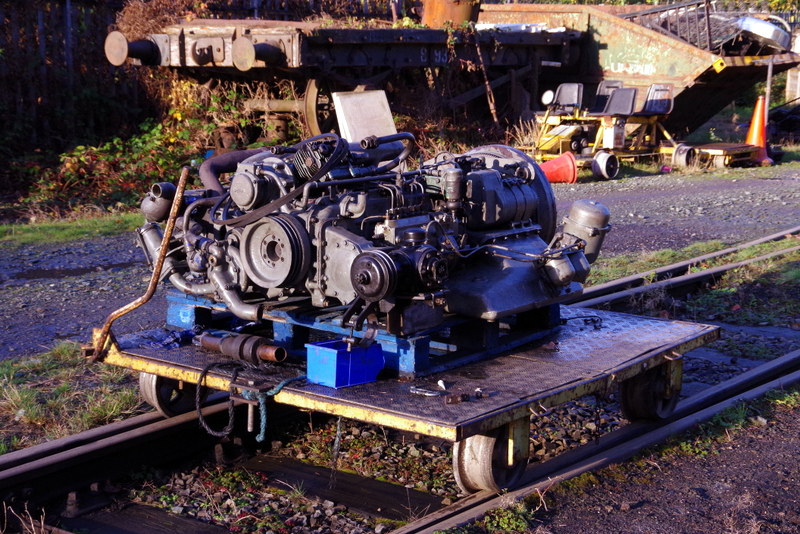

Readers of the previous report may remember the proclamation, by our engineers, that there was a good chance that the rebuilt no. 1 engine would be started for the first time this weekend. That is indeed what happened and, shortly after the lunch break, it was wheeled out of the shed to an audience of excited onlookers...

The following video shows the very first start which took place without so much as a dress rehearsal...

... and the following one was filmed a few minutes later when the engine had settled down and begun to appreciate how it was expected to behave...

On the Sunday morning, the job of returning the engine to its rightful place began with the shunting of the power car to the lifting jacks, lifting the body, and removing the bogies to provide a clear space underneath. The following picture shows the vehicle in the air and also provides a bonus glimpse of the shiny, new 'canvas' that is in the process of being fastened to the corridor connection...

The no. 2 bogie had to be moved well clear to make way for the engine-carrying trolley...

On the face of it this vehicle has such a high power-to-weight ratio that it ought to be adorned with 'go faster' stripes ...

... but the 150 horsepower engine turns out to be incompatible with the 'feet on ballast' transmission system so it has a maximum power rating of two manpower...

The engine was lifted and fastened in position (much more difficult to do than this single sentence suggests!)...

... and a start was then made on reinstating the various auxiliaries and connections...

That job will be completed on a future occasion and the engine should then be able to play its part in powering the vehicle once again.

Before the Wickham can be used again it is due a 'B' examination which includes various bogie-related jobs such as the checking of the final drives and the lubrication of the brake gear. Those are much easier to do when the bogies are out in the open...

With the bogies bathed in daylight it was also possible to get an unusually clear picture of the innards of a final drive...

Further work was carried out to secure the new 'canvas' to the corridor connection of 50416. Some rotten wood had to be replaced and it was also necessary to experiment with various types of fastening to find the optimum one.

Two more doors were taken off for stripping down and three that have been processed were reinstalled.

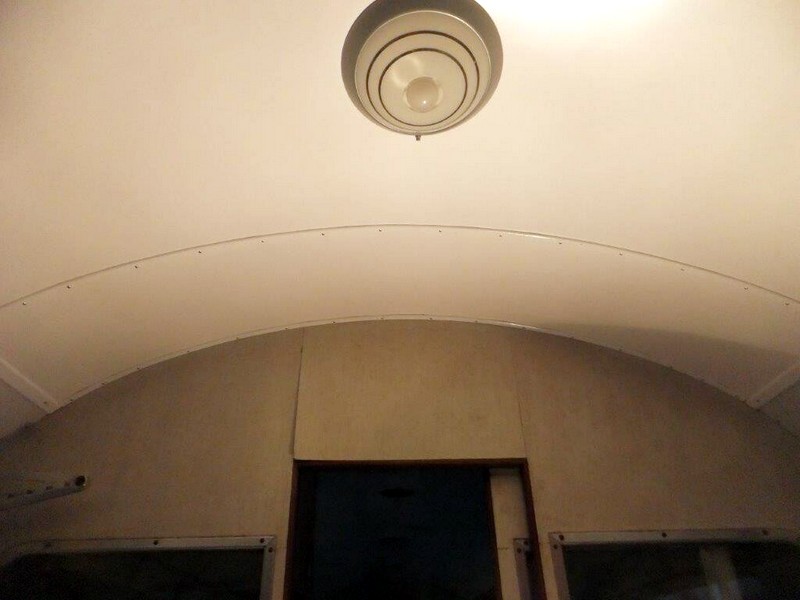

The last wall panel was fitted in the 1st class and that was followed by the fitting of the first three beading pieces to cover the joints on the ceiling as well as three of the ceiling lights. The following picture shows a ceiling bead and one of the lights...

The door jamb that has caused a struggle for many years was eventually fitted...

It is to be hoped that the other thirteen will turn out to be somewhat easier!

Thanks to Allen Chatwood, Dave Coogan, John Joyce, Mike Martin and Martin Plumb for supplying the pictures and videos.

We were delighted to receive some recognition of the part that we played in helping Llangollen Railway back to its feet (or back to its rails?) this year in this recent Article in Llanblogger, a news blog site that covers Llangollen-related news.

Our running season was scheduled to end on Thursday 4th November but the hybrid class 104/108 was pressed into action for the next three days as a steam replacement. The following sequence of pictures shows it passing Pentrefelin with the 15.10 Llangollen-Carrog service on Saturday 6th November.

To facilitate the use of larger screws in the filler pieces above the windows it was necessary to drill larger holes and countersink them...

The aluminium full window surrounds were retrieved from the store and fitted in the two windows on the driver's side of the first class section...

We accept that trying to spot the aluminium trim in the above picture could serve as an optician's eye test so we will endeavour to provide some better pictures in the future.

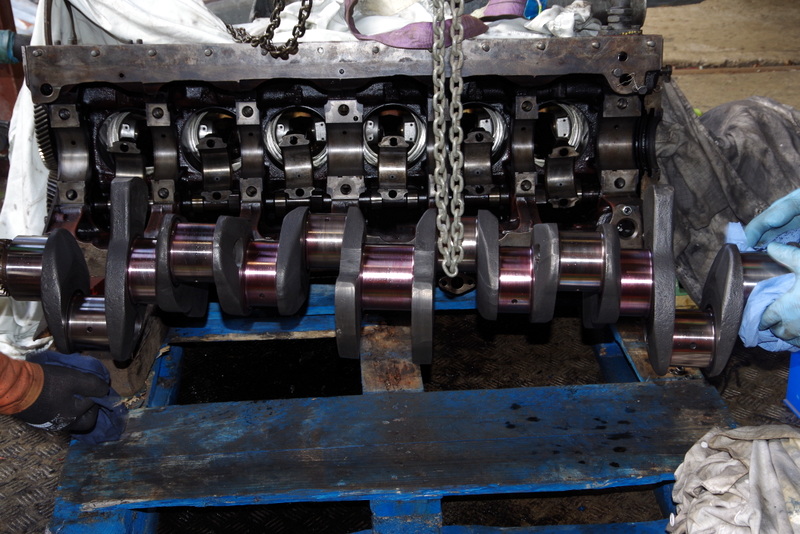

Following some initial confusion caused by the availability of two flavours of big end bearings, only one of which was required, two long days were spent painstakingly assembling things in the right order to rebuild the no. 1 engine...

The following pictures show the engine at the close of play on Sunday, by which time it was almost assembled (with only the fluid coupling, injectors, oil filler pipe, and a few sundry bolts to sort out) and the engineers in charge were making noises suggesting that the engine could well be doing the same at the next meeting in a fortnight's time.

Oh - and they even remembered to install the most up-to-date Leyland 680 firmware! ;-) ...

On the unit itself a start was made on fastening the recently acquired 'canvas' to the corridor connection of 50416. After first of all cleaning and painting some of the framework...

... a start was made on securing the 'canvas' to the gangway aperture to which it is secured by timber strips at the sides and the top and a metal fall plate (the metal plate that you walk on between vehicles) at the bottom. As with most jobs there were some difficulties, one of which was that the fall plate didn't want to let go of the vehicle, and the other of which was that the circumference of the canvas was deemed to be roughly 2% longer than that of the opening - something that seems insignificant in writing but more of a problem when trying to 'lose' the spare. Lessons that we learn as a result of fitting this one may result in a revision of the design for subsequent ones - something that was expected from the outset.

Class 127 vehicle no. 51618 (undergoing bodywork repairs at Llangollen)

The next door to be processed on the secondman's side of the vehicle was dismantled and, in keeping with the general theme, the trim panel let go fairly easily but the removal of the pull board was something of a trial as three of the four screws wouldn't shift. When it was eventually removed it was followed by the door lock and scissors which were sent to the parts refurbishment department. At least the person doing such a job is provided with a sense of satisfaction when it finally reaches the required conclusion...

Thanks to Allen Chatwood, Dewi Davies, John Joyce and Mike Martin for supplying the pictures.

The hybrid class 104/108 unit and the class 108 have, between them, provided train services on a number of days since the previous report, including three consecutive days when they worked together as a 4-car unit. The following picture, which was taken on Wednesday 27 October, shows the 4-car unit waiting to return to Llangollen from Carrog with the hybrid unit leading...

The afternoon of Saturday 16 October saw something out of the ordinary at Llangollen when two unidentified biplanes flew over while the hybrid class 104/108 was resting between trips...

We don't usually find ourselves wishing for rain but we did just that after we repaired the driver's windscreen wiper on 50454 (at one end of the hybrid unit) on 10th October and were keen to test it with some real (persistent) Welsh rain after carrying out a cursory test under 'laboratory conditions'. Much to our surprise, for October at least, the unit managed to complete five full days without the wiper being needed at all before the rain finally arrived with a vengeance on 20th October and the repair was declared to be a success!

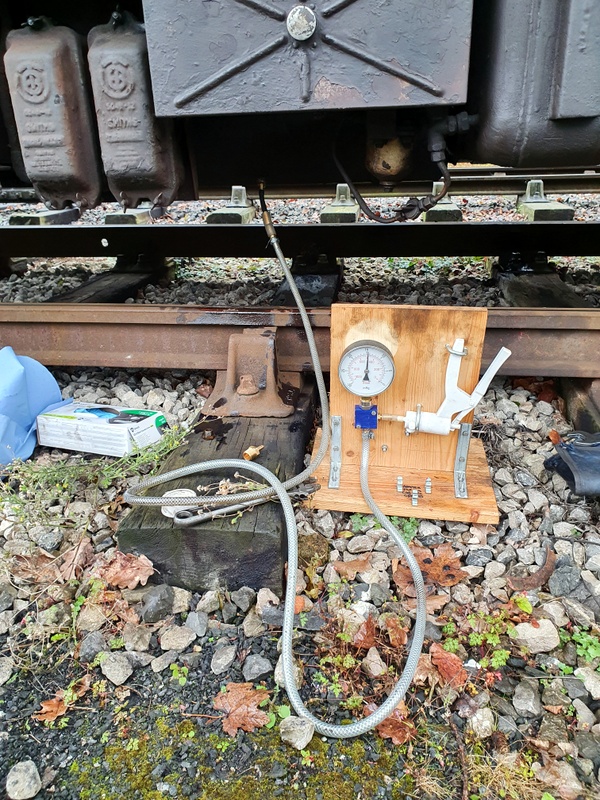

After the unit was given its scheduled Fuel Point (FP) exam some further work was carried out to try to determine why it is poor at creating, and maintaining, vacuum...

It was discovered, amongst other things, that the auto-isolating valve on 50454 was set low (14" Hg instead of 19" Hg) so it was adjusted to the correct value. The function of the auto-isolating valve is to retain 19" vacuum in the reservoirs when the vacuum drops below that value in the release pipe which is one of the pipes that runs all the way from one end of the train to the other. The adjustment of the valve should, at least, mean that less time will be needed from now on to recreate the required amount of vacuum in the reservoirs when the engines are started after each layover.

It may come as a surprise to learn that the latest stage of the restoration involved dismantling some things that had recently been constructed: the luggage rack panels and the filler pieces in the centre compartment were taken down, the two large outer panels were cut down by 3", and the cut-down panels were then refitted with a new panel made to fit between them. Why? The reason for all of that work was to move the joints away from the luggage rack brackets where covering them would have been impossible - something that demonstrates the team's desire to produce a quality finish!

The metal upstands in the two second class compartments on the secondman's side were given a second, and final, coat of gloss paint.

The aluminium bead that sits between the luggage rack panel and the ceiling was measured, cut and fitted on the driver's side of the first class section and the little vertical pieces were also cut and fitted as shown in the following pictures...

The vehicle was also given a long overdue external clean. It had accumulated a good coating of the green 'gunge' that tends to coat things under trees and/or in damp areas, and even a bit of lichen. After much scrubbing and hosing it looks presentable and the people working in it no longer feel as though they are working in a fish tank! Flushed with the success of that we may give our Mk 2 mess coach some similar treatment in the near future!

A start was made on reassembling the faulty no. 1 engine using an 'A' frame to suspend the crank so that it could be manipulated into its new home...

The new main bearings went in without too much drama but various other things, including the big ends, produced some puzzled expressions and presumably some accompanying sharp intakes of breath!

Following the recent delivery of a new corridor canvas the old one was removed from the power car in readiness for the new one to be fitted...

Beading was fitted to the ceiling / luggage rack backing panels in 1st class with both sides being completed...

A start was then made on fitting the wall panels to the driver's side wall in 1st class...

Other work included the construction of templates for the cab windows (not helped by the different angles) and a door jamb that is proving to be sufficiently awkward that it has been taken away as a "homework project" on at least two occasions!

Thanks to Allen Chatwood, John Joyce, Mike Martin and Martin Plumb for supplying the pictures.