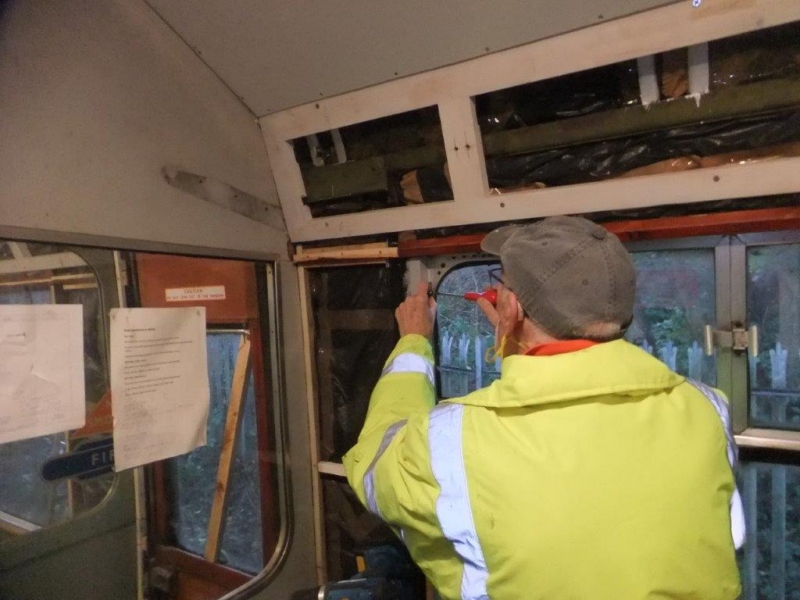

In the Cravens, the team beavered away wiring up the 4 remaining speakers, and various parts of the cab, as well as fitting more insulation. A milestone was reached with a dry fitting of the first of the new wall panels, in the first class saloon. Work was also undertaken to clean out the gutters, sliding lights, and fettle the drainage holes.

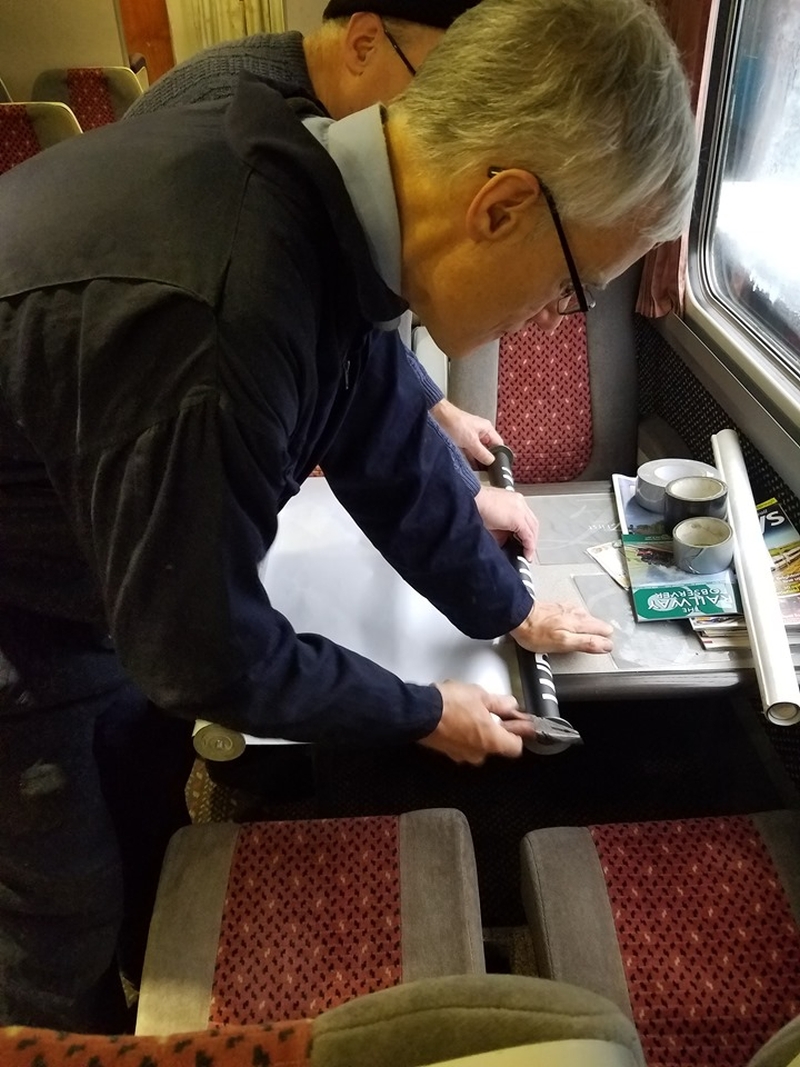

The Wickham was fitted with the "new" destination blinds, this involved a fiddly process of cutting the blinds down to different sizes, as the trailer car, was different to the power car, which was different to the standard sizes used on the rest of the fleet. The video below shows you all of the destinations now on offer across the fleet!

The 104 M exam was also progressed over both days of the weekend. As ever it seemingly takes twice as long to do everything as you have two power cars rather than a power car, and a trailer car. The light fittings have been dropped down and cleaned, the driver's brake valve cleaned and lubricated, the engine oils and filters changed, the air filters changed; after quite a battle in various ways with parts of 50447 used in places.

Over at the Midland a landmark step has been made in the restoration of the Gloucester, as the headlight has been illuminated for what we believe is the first time since the 1980s. Positioning of some of the new switch panels can also been seen in the photographs. Five windows have also had the sliding lights refitted.

On the running units at the Midland, the 108 is now fitted with LED bulbs, and the 141 has had work done to the gangway corridor.

A small working party on Saturday set into the bodywork around the guards van area on 51618. For a change it's not as bad as we expected it would be. Some work will also need to be done to the roof to replace an earlier patch with a welded version. Work also took place in needle gunning the front of 56097. The temperatures were quite cold as witnessed in the photo!

On Sunday a team set into antifreeze checks on the fleet. Rusty was witnessed laughing at members working in the cold weather.

A sliding light which had fallen apart was removed from 54504 and replaced with a ply version while the original can be prepared.

A door which had been reported as faulty in 50454 was investigated, with no fault found. However the lock was stripped down and greased.

The M-Exam on the 104 was also started, mainly in the electrical areas.

In the 105, the day was spent cutting and fitting vertical timbers to the vestibule walls ready for the wall panels to attach to. Quite a bitty job, but one that is essential.

Another busy week of operations, with the 104 out each day of the week, on some days carrying over a hundred people!

The secondmans side of the Gloucester has been treated to some new steps, which have been freshly painted. Work has also started on fabricating a steel plate that will allow the 4 jumper cables to enter the cab on the secondmans side, and reach the terminal board. Next up is to fit the conduit.