The class 104 has been 'gift wrapped' to keep the weather off it whilst it is stored pending heavy bodywork overhaul. A partial victory for forward planning in that the exhausts are uncovered; only partial, however, as there isn't an easy way to get in and put the control key in to start it!

It's not just about the trains themselves. The above picture shows one of our volunteers carrying out the Portable Appliance Tests (PAT) on electrical equipment around the depot.

During last weekend's working meeting at Pentrefelin we had two important visitors, both of whom came to see how the other half live (as it were). The Railway's General Manager tried his hand at cutting gaskets from cork sheet for the axlebox covers on the class 127 vehicle 51618 which has different bearings to all of the other vehicles in the fleet...

Meanwhile, the Heritage Engineering Manager, which is intended to be read/parsed as (Heritage Engineering) Manager [not Heritage (Engineering Manager)] was given an explanation about the finer points of the class 127's auxiliary equipment before allegedly remembering an urgent appointment elsewhere when it was suggested that his orange jacket was much too clean...

The 'Unit-specific work' section below gives a flavour of the work that has been carried out on our railcars.

A recent recruit learning how to refresh the grease in the axlebox bearings.

Another recent recruit cleaning out old grease from the axle bearings on Wickham trailer 56171.

The new 'toy': a cordless grease gun. "But grease guns don't have cords," as some wag pointed out. True but this one is a lot more friendly (until the battery runs out at least).

Making use of the 'new' technology.

Attending to various studs for the axleboxes of 56171 with a die nut and file.

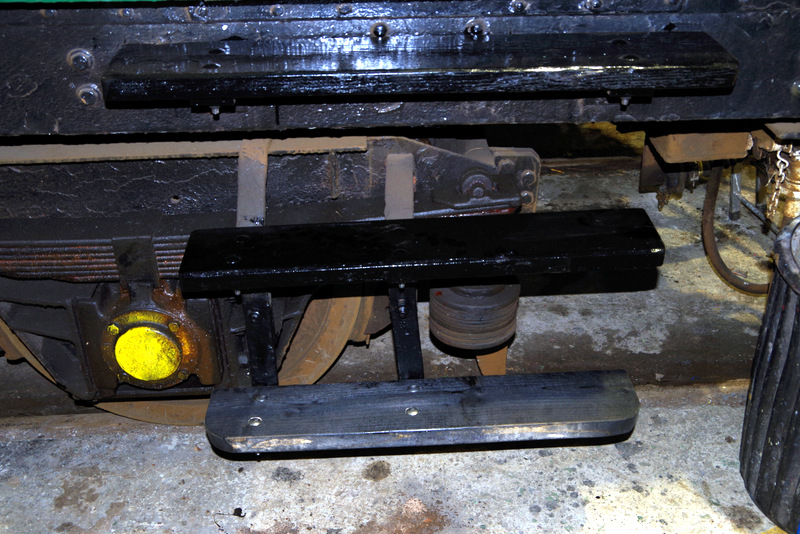

Taking steps ... or rather refitting them. 56223 receives a new hardwood step for the secondman.

Refitting the driver's side radiator to 51618. It was removed a few weeks ago, for access to the compressor / fan drive gearboxes. It also got thoroughly flushed out - looking at what came out, probably for the first time in several decades.

Refitting the fan drive shaft to said radiator / fan assembly.

Compressor refitted with new stainless delivery hose and "modern" fittings.

In what seems to have become a department tradition, a new volunteer deals with axle bearings on class 127 car 51618.

Thanks to John Joyce, Andy Lowe and Mike Martin for supplying the pictures that were used in this edition.