There are no prizes for spotting that more than six weeks have gone by since the previous report. That was entirely due to the editor's absence/workload and not because of a lack of news. Far from it because it has been a very busy period for the group, both in terms of the provision and crewing of trains and also their maintenance and restoration. The maintenance regime comprises annual exams and mileage-based exams and in recent weeks the latter have exhibited a behavioural characteristic that is normally associated with buses thanks to several of them turning up at the same time! The volunteers who work at the Midland Railway, Butterley have also been busy with the continuing restoration of the Gloucester Class 100 unit.

I will attempt to describe some of the things that have happened in the sections below.

Nearest the camera is the hybrid class 127/108 unit and that is followed by the class 108 and the Wickham class 109.

Looking from the other end they look like this and it will be left as "an exercise for the student" to work out which unit is which...

Since the previous report our railcars have been used to provide train services on approximately twenty five days with the provision of 'A' timetable services, 'B' timetable services, private charters, and our contribution to the Classic Transport Weekend on 6/7 July and the Sixties Weekend on 3/4 August. All of the services were provided by classes 108, 109 and the hybrid class 127/108 - on some occasions as solo 2-car units and on other occasions as 4-car combinations.

The following picture was taken from an unusual angle by James Hilton and shows the 4-car Class 109 plus hybrid class 127/108 (with the class 127 vehicle nearest the camera) at Glyndyfrdwy with the 11.05 Corwen - Llangollen service on Thursday 04/07/24...

A start was made on the 'C' exam that needs to be completed on 50528 before it can run again. The 'C' exam is the second largest one that we do and requires something in the order of eighty checks and jobs to be signed off. One of those jobs is "Final drive cardan shaft, freewheel shaft and freewheel lubricate" that requires various transmission components to receive a visit by a grease gun...

Please note that it is not a requirement for volunteers to provide confirmation to their fellow workers that they are wearing the correct glasses for the job. I think this can best be described as a personal reminder appliance :-) ...

The sliding gear and bottom runner for the end door was cleaned to a very high standard and the latter was then given a coat of yacht varnish to try to keep it shiny. Aside from needing some bolts to fasten the door to the sliding gear, it is now ready for a test fitting.

Although the vehicle has been fitted with a sloping floor to match the original Cravens design, it became necessary to remove the slope from the area between the rear wall and the location of the rearmost seats in order to provide a flat surface for the sliding door runner.

Elsewhere on the vehicle the scissors that support the corridor connection were fitted...

...the complex door frame section was bolted into place...

...work progressed with the fitting of draught excluder strips around the doorways...

...and the toilet shelf unit that had been returned following a homework project now awaits a rub down, staining and varnishing...

In addition to the usual checks and jobs, the following were carried out during a 'B' exam:-

The 'scissors' were replaced in the driver's door of the power car (51933), the droplight of which had developed a habit of getting stuck in the fully-open position...

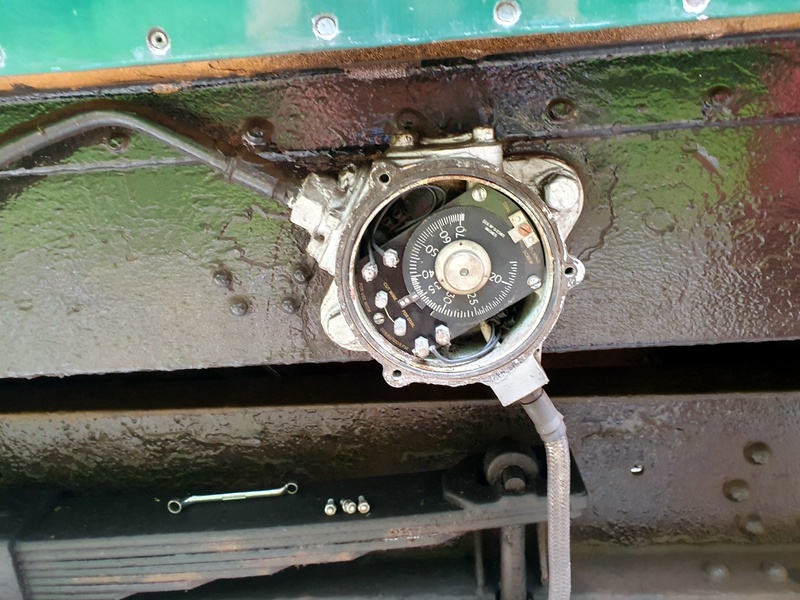

The driver's brake valve in 51933 was dismantled, cleaned, lubricated and reassembled. This becomes necessary every so often because a valve that is stiff to operate makes driving with finesse difficult. The following picture shows the dismantled valve...

Some stepboards that were deemed to have passed their best-before date were removed...

...and replaced with some newly-constructed ones on which we are trialling some non-slip strip recommended by the North Norfolk Railway...

A faulty air pressure switch was replaced underneath the power car (51933). The switch is designed to provide confirmation to the driver that the final drive has sufficient air pressure for reliable operation but this particular one had taken to providing that confirmation irrespective of the air pressure.

Installing the new one in this cramped position was not easy and was carried out by someone who had come to spend a day or two with us to find out "how the other half live"...

The tried-and-tested method for checking for air leaks is to squirt some soapy water and look for emerging bubbles...

The Wickham became due for a mileage-based 'A' exam during the period and is seen here with one member of the team carrying out a repair to a door and another two doing the brake checks/adjustments...

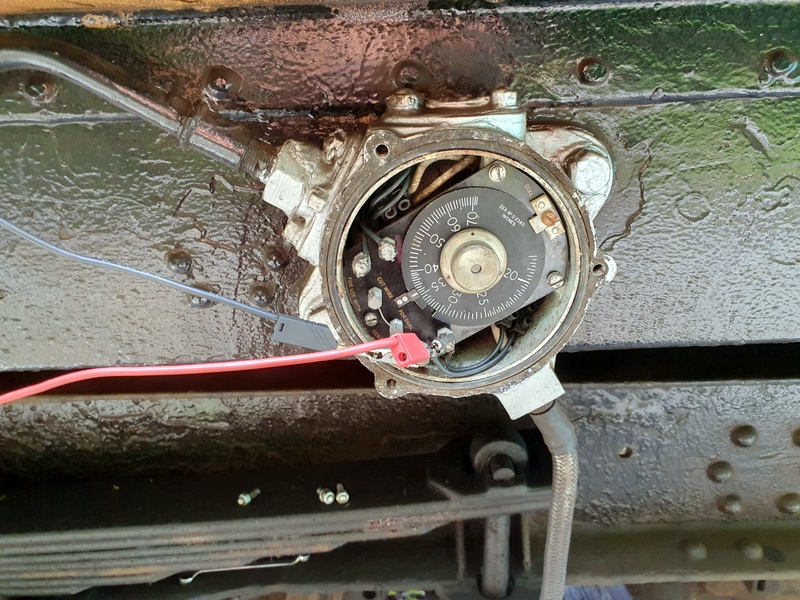

When the speedometer stopped working in the cab of the trailer car (56223) an electrical fault was thought to be the most likely cause.

The signal is created by an axle-driven generator and sent to the speedometer via a box on the solebar that includes an adjustable compensator for wheel wear...

...so there is some scope for bad contacts etc. However, in this case the electrical system turned out to be completely innocent because the injection of a test voltage caused the speedometer to spring into life...

It turned out that the problem was a mechanical one because the drive pin that is screwed into the end of the axle to drive the generator had sheared off...

Although we were able to find a spare pin it was in a poor condition and, in any case, the spare tapped holes in the end of the axle turned out to be on the wrong diameter. The remains of the original peg defied attempts to remove it, so eventually the hole was tapped out and a new peg manufactured from a Leyland rocker stud.

The electro-pneumatic (EP) valves on the power car continue to cause occasional problems by rapidly losing the supply of compressed air. The underlying problem has still to be determined but, in the meantime, the drivers who have fallen victim to it are becoming more adept at applying the fix.

Work continued with the installation of wall and ceiling panels including this one being fitted above a vestibule door...

A start was made on installing the holes and wiring for the speakers for the public address system...

...followed by some speakers...

The outside is also being spruced up as can be seen in the following picture which shows the power car being painted...

Thanks to Allen Chatwood, James Hilton, John Joyce and Martin Plumb for supplying the pictures that were used in this edition.