The Railcar Gala will this year take place during the weekend of 5-6 October...

Here are the Timetable and the Graphical version of the timetable.

For further information see llangollen-railway.co.uk/railcar-weekend

Last weekend saw some "all hands to the pumps" preparations for next weekend's Railcar Gala.

The hybrid class 127/108 and the Wickham class 109 were cleaned inside and out.

Was this a case of a staff bonus, the humming of a 1970s song by Rose Royce, or someone just not knowing when to stop? ...

While supposedly mopping the floor inside the Wickham, one member of the group just managed this 'grab shot' of the Pannier Tank no. 7754 passing Pentrefelin with the 14.45 Llangollen-Corwen service...

Possibly another staff bonus?

The class 104 hasn't yet run, and has rarely seen the light of day, this year because it has been undergoing a 'C' exam inside the shed as and when time permitted. Following the completion of said exam, the unit was cleaned on the inside and given a serious amount of sprucing up on the outside so that it looks its best for its 2024 debut at next weekend's gala...

The Wickham class 109 was given a mileage-based Fuel Point (FP) exam...

... before being used as the yard shunter to rearrange some wagons in a siding...

The aim of that exercise was to finish up with the brake van and hopper wagon that will provide the tail load on some of the gala trains in the right place and the right order...

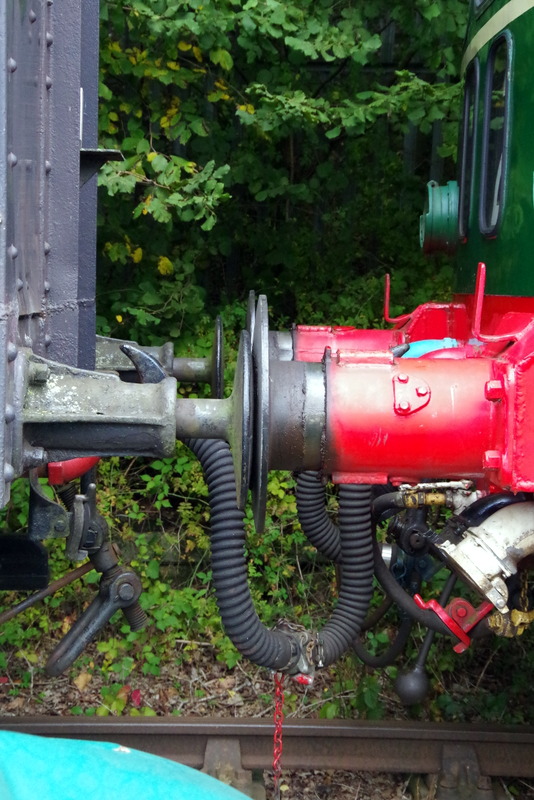

The Wickham class 109 was then used as a vacuum donor (air receiver?) to test the air-tight quality of the brake pipes and seals etc. on the vacuum systems of the wagon and brake van...

Some improvement was made with a bit of TLC (tender loving care) and the replacement of some components including some of the washers that provide the seals between pairs of brake pipes between vehicles and between brake pipes and the 'dummy' connectors on end vehicles...

As is usually the case in the run-up to a gala event there was a shunt-a-thon to swap around the positions of the units and the yard at Pentrefelin gradually took on the appearance of an erstwhile DMU depot...

Wooden blocks were constructed and bolted to the roof supports in order to provide fastenings for the ceiling joists...

The installation of wall panels continued with some lower wall panels...

Some panels were also installed on the rear wall, the angle of which dictated that the length had to be cut into two pieces and the joint angled...

The forth window frame was fitted in the middle compartment on the driver's side along with the beading, thereby marking the completion of that wall...

...and more ventilator/speaker covers were installed...

A hunter/gatherer mission resulted in the toilet door being located but it looks as though it will need a bit of TLC (Tender Loving Care)...

Thanks to Allen Chatwood, John Joyce, Mike Martin and Martin Plumb for supplying the pictures that were used in this edition.

The Railcar Gala will this year take place during the weekend of 5-6 October...

Here are the Timetable and the Graphical version of the timetable.

For further information see llangollen-railway.co.uk/railcar-weekend

Since the previous report, the 4-car Wickham class 109 + class 108 combination has been busy providing all of the timetabled services and the Wickham has also worked solo for some private charter services.

On Sunday 25/08/24 the 4-car set was sent on an errand to collect some light fittings from the locomotive yard prior to heading Empty Coaching Stock (ECS) to Corwen to play its part in providing the 'B' timetable service. It is seen here, with the Wickham class 109 trailer car (56171) leading, waiting at the approach to the locomotive yard while a crew member carried out a reconnaisance mission to establish the required route and set the points accordingly...

Work continued on the 'C' exam on 50528.

Having discovered that one of the primary bevel gears in the no. 2 final drive had lost a tooth we set about replacing the bevel gear. The cardan shaft had to be removed for access, but thereafter the job was dealt with fairly straightforwardly, to the surprise of those involved. The main bevel gear didn't show any sign of damage, so it's all back together again.

It seems to be the year for stepboard replacement because, shortly after a number were replaced on the class 108, attention has now turned to those on the class 104. The ones that were deemed to have passed their use-by date were removed and new ones constructed...

After the picture was taken, the next steps (no pun intended!) were to paint them with some chassis black, add a non-slip strip and fit them to the class 104.

Other work included removing numerous layers of paint off the cab roofs prior to adding a coat of fibreglass resin, dealing with some door problems, restoring the yellow fronts on the cabs with paint and/or varnish, and cleaning/painting the solebars.

Two panels were cut and fitted to the rear wall...

...and panels were fitted at the sides of the door in the rear vestibule...

The class 108 was given a mileage-based Fuel Point (FP) exam that turned up little of note apart from the need to adjust an exhaust bracket on the back of 51933.

Wickham Class 109 50416/56171

The Wickham was given a mileage-based Fuel Point (FP) exam.

The secondman's door in 50416 was given some attention where it had been sticking...

From a distance it looked as though these two people were engaged in a Rubik's cube competition...

...but closer inspection revealed that they were, in fact, 'playing' with 'snaplock' switches of the type that are fitted to the final drives of our railcars in the hope of establishing (a) exactly how they work, and (b) what, if any, scope for subtle adjustment there might be.

A switch is mounted on each final drive to sense the position of the sliding dog and provide confirmation as and when one or other of the directions (forward or reverse) is properly engaged. It had been discovered that one of the switches on the Wickham had taken to providing positive confirmation even when no direction was engaged so it was initially thought that the solution was simply to swap the switch for a known good one. Unfortunately, it turned out to be much more involved than that and it was only after a couple of switches had been dismantled and some components swapped between them that a reliable setup was eventually produced.

Three window frames were fitted in the middle compartment on the driver's side along with some beading. The following photograph was taken when two of the window frames had been fitted...

Externally, the recent paint job has really transformed the unit...

Thanks to Allen Chatwood, John Joyce, Andy Lowe and Martin Plumb for supplying the pictures that were used in this edition.