During the weekend of 1/2 June most of the coaches that normally live at Pentrefelin were taking part in the Diesel & Industrial Heritage Gala so our railcars were able to 'stretch their wings' a bit. Our roving photographer, Mike Martin, took the following photograph of the resultant railcar depot from a passing Diesel-hauled train...

From left to right the vehicles facing the camera are class 108 no. 54504, class 108 no. 56223 and class 104 no. 50528.

At our recent working meetings most of the effort has gone into the completion of the 'M' (major) exam on the Wickham class 109 unit (shown in the above photograph) so that it can return to service later this week. Some information about the work that has been carried out on that and our other railcars, both at Llangollen and Butterley, can be found in the 'Unit-specific work' section below.

Since the previous report, train services have been provided by the class 108 and the hybrid class 127/108, mostly individually but also in multiple on days when a 4-car unit was required to provide the necessary seating capacity.

...and later at Carrog...

The following picture shows the hybrid class 127/108 on its way back to the depot after the close of play on Friday 31/05/24...

As well as draught excluder being fitted around the doors, much cutting and chisel work went into the 'fettling' of the frames that go either side of the vestibule doors...

The following picture gives an idea of what the panelling at the side of the door will look like upon completion...

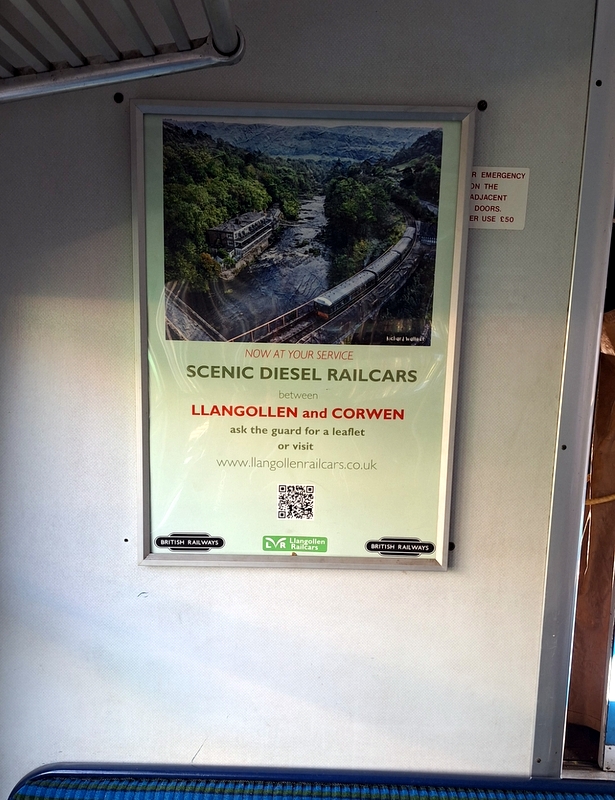

The class 108 was given an 'A' exam and, in addition to that, it received some newly-created posters...

The 'M' exam was completed with a number of jobs including the following...

Repairs to doors required some attention to woodwork such as this at the top of a guard's door...

...as well as the removal, adjustment, and replacement of some locks using shims that had to be specially constructed...

Further investigations were carried out to try to work out why rainwater still manages to find its way through the recently-refurbished roofs. As a start a ventilator was removed and examined, and some rivets were replaced...

The radiators were steam-cleaned...

Following the problem in which a burst pipe was caused by us failing to 'winterise' the unit properly, the pipe that was found to run uphill was replaced with one that pointed downhill and, at the same time, a more convenient drain valve was fitted...

The vacuum gauges were checked using the calibrated master gauge...

The unit was given a Fuel Point (FP) exam which included the checking and topping-up of the oil in the final drives...

As can be seen in the above picture the job requires one person to crawl underneath to check the oil level and aim the end of the pipe in the right direction for the top-up, and another one to pump the oil as required.

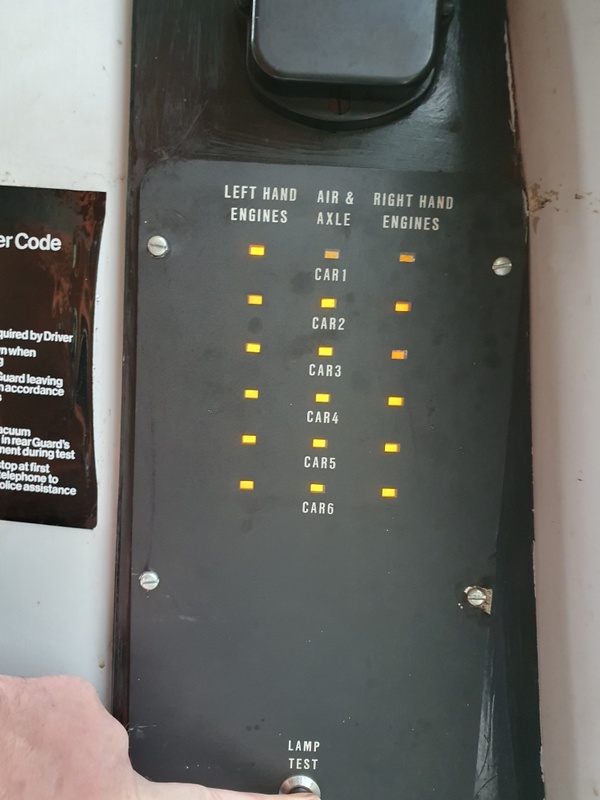

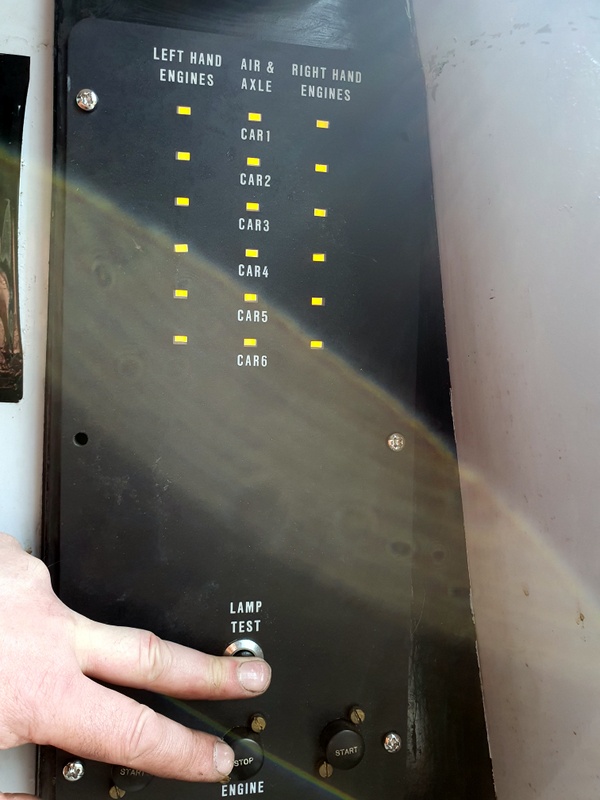

Some of the Light Emitting Diodes (LEDs) on the Engine/Air & Axle panel in the cab of the trailer car (56223) had become rather lazy and were not lighting up properly...

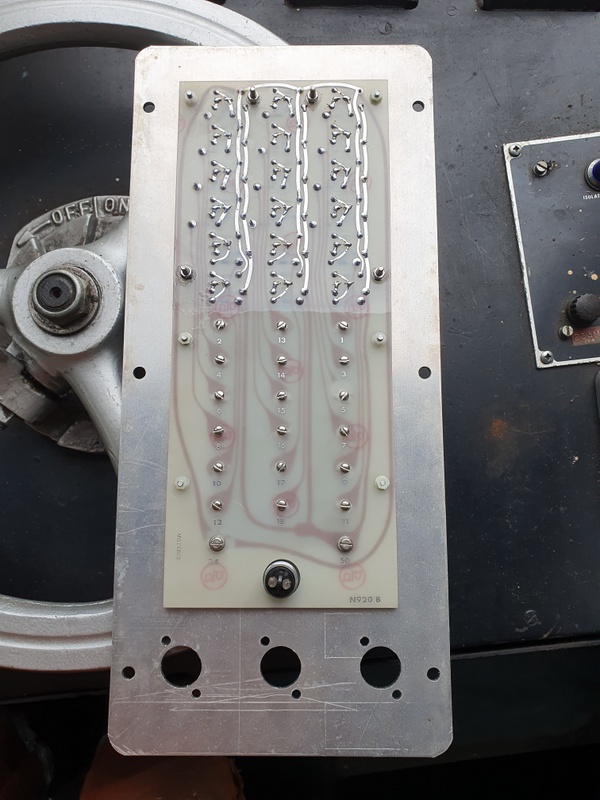

so the panel was replaced by a shiny new one...

The job entailed carefully transferring all of these wires from the old panel to the new one in the right order...

Success!

The panel shows the driver which engines are up-and-running and also provides confirmation that the final drives have sufficient air pressure for correct operation and have engaged the forward or reverse direction as appropriate. The columns marked 'Left Hand Engines' and 'Right Hand Engines' show the state of the engines (lit=up-and-running) along that side of the train starting with the one nearest the driver at the top. The column marked 'Air & Axle' shows the state of the corresponding final drives (lit=good).

Regrettably, 56223 became a victim of mindless vandalism when one of its windows, and three windows on another of the Railway's coaches, were broken overnight on 15/16 May...

Beading work continued with measuring, cutting, testing, painting and fitting. The following picture shows the trial fit of some of the beading above a vestibule door...

Thanks to Allen Chatwood, John Joyce, Andy Lowe, Mike Martin and Martin Plumb for supplying the pictures that were used in this edition.