Please consider turning your everyday online shopping into FREE donations that will help to support the maintenance and restoration of our railcars. You can do that by shopping via https://easyfundraising.org.uk/causes/llangollenrailcars/ or, in the case of Amazon purchases, signing up to Amazon's fundraising site https://smile.amazon.co.uk and choosing Llangollen Railcars as your chosen charity. Each eligible purchase will then result in the online store making a small donation to our charity. Every little helps so thanks in anticipation of your support!

Information about the work that was carried out on the DMU vehicles at Llangollen and Butterley during the fortnight since the previous report can be found in the "Unit-specific work" section below.

Work continued on tidying up the woodwork and ceilings in various parts of the unit including this vestibule in 50454...

A new feed valve was trial-fitted to 50454. A feed valve limits the amount of vacuum that can be created in the train brake pipe to 21" when the supply is 28" plus and resides under the driver's desk as can be seen in the centre of the following picture. The diaphragms in the original British Railways (B.R.) valves eventually perish and our replacement ones are not really ideal so, as an experiment, this new one has been produced to the original B.R. specification. It performed correctly.

The metal upstand on the secondman's side of the large middle compartment received its first coat of gloss paint...

... and the timber beading that hides the joint between the wall panels and the metal upstand was installed on the driver's side of the first class section ...

If you find it difficult to differentiate between the metal upstand and the timber beading in the above picture please put that down to the quality of the work rather than the quality of the picture.

What started out as an exercise to repair a water-damaged section of roof in the guard's van has turned into a more extensive refurbishment of the van with much sanding and application of primer taking place...

During a normal operating season this type of work could only be carried out in bite-sized chunks if the unit needed to remain in a fit-for-traffic condition. However, with no requirement to run trains for the time being at least, the opportunity has been taken to 'go for broke' and do a 'proper job'. It looks as though the time has come to ensure that there is plenty of 'Goose Wing Grey' gloss paint in stock!

Class 109 (Wickham)

The repaired no.2 vacuum brake cylinder and associated brake gear was refitted to 50416...

and then the two vehicles were reunited...

This turned out to be the first lesson in coupling vehicles for one of our newer members who effectively started with the advanced lesson because coupling two intermediate vehicles is much more difficult than a cab-to-cab connection due to the need to crouch under the gangway.

Class 127 vehicle no. 51618 (undergoing bodywork repairs at Llangollen)

Repairs to the bodywork continued...

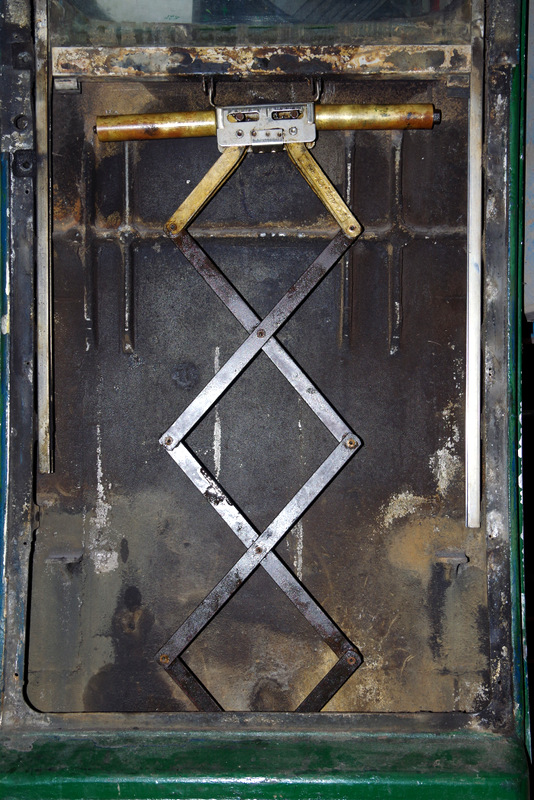

... and focussed mainly on the doors, each of which is being removed in turn and serviced to ensure that everything works properly. That includes the cleaning and servicing of the door handle mechanisms and the scissors (the spring mechanism associated with the droplight windows). The work is definitely paying off because the doors that have been serviced now open and close easily and close with a satisfying clunk. Perhaps we could recreate the sight and sound of St Pancras station in the 1960s and 1970s when it is back in traffic?

Some more bits of the chassis were subjected to needle-gunning and various items that had been removed and placed on a bench were painted.

One of the fixed windows that had to be removed prior to the replacement of the body side was trial-fitted and proved that the aperture had been constructed to the correct shape and size...

The new woodwork in the guard's van was given its first coat of 'Goose Wing Grey' gloss paint...

Class 100 trailer car no. 56097 (undergoing restoration at the Midland Railway, Butterley)

Newly-arrived panels to go between the ceiling panels and the ones behind the luggage racks were cut to length, drilled and fitted...

and more insulation was fitted to the driver's side wall of the rear compartment...

Thanks to Allen Chatwood, Jim Jeffrey, John Joyce, Mike Martin and Graham Parkin for supplying the pictures

Last Saturday saw the unveiling of the group's entry for the 'Novel chairlift' competition...

Just kidding! For the real story please see the Class 109 section below.

During the fortnight since the previous report, a variety of work has been carried out on both sites (Llangollen and Butterley). Further detail can be found in the "Unit-specific work" section below.

Work continued on tidying up the woodwork and ceilings in 50454 with varnish and paint respectively and a repair was carried out to a section of gutter that had come adrift.

More pieces of wall panelling were cut and fitted in the large second class saloon...

... and new timber mouldings were made for the joint between the floor and the metal upstand...

Also visible in the above picture is the first section of beading to cover the joint between the wall panel and the metal upstand. The masking tape was used to mark out the positions of the screw holes.

In the cab the resplendently-restored brake controls were trial-fitted and will be fitted properly at a later date...

A newly-produced air pipe was fitted to 54504, to replace the cracked cast-iron dirt trap in the air supply to the cab, and the unit now makes, and holds, air once more.

Further sanding was carried out in the guard's van to get the interior ready for painting.

A minor exhaust leak at a joint was repaired using some exhaust paste and a large clamp.

Class 109 (Wickham)

The bronze bush needed to repair the no.2 vacuum brake cylinder on 50416 had arrived and is seen here alongside the one that was removed...

Clearance between the piston rod and bush should be about 0.005" but was roughly ten times that with the original bush - something that was deemed to be responsible for an excessive number of failures of the associated gland. The cylinder was then tested using a cast-iron rail chair as a dummy load and the class 104 to create (and destroy) the vacuum as required ...

After the prescribed tests were carried out the piston was left in the "brake fully applied" position and it was still in the same position one day later which proved that there was negligible leakage past the rolling ring. The cylinder was therefore given a clean bill of health and will be reinstalled under the vehicle at the next opportunity.

Class 127 vehicle no. 51618 (undergoing bodywork repairs at Llangollen)

Repairs to the bodywork continued...

This vehicle is the only high density (aka suburban) one in our fleet. High density means that each seating bay has its own passenger door - something that facilitated the rapid boarding and alighting of passengers during the vehicle's initial life as a so-called 'Bed Pan' unit when it provided commuter services between London St. Pancras and Bedford. An obvious disadvantage of having so many doors is that it presents more of a maintenance headache and the work that is currently taking place includes the laborious task of servicing each of them in turn to ensure that everything works properly. That includes the cleaning and servicing of the door handle mechanisms and the scissors (the spring mechanism associated with the droplight windows)...

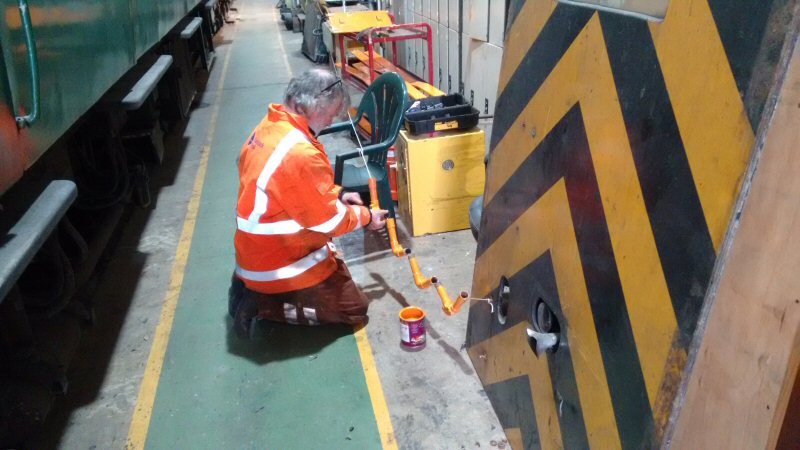

The seemingly never-ending task of stripping paint from, and applying paint to, jumpers and other items continued although, surprisingly, the orange paint stayed in the cupboard this time...

Class 100 trailer car no. 56097 (undergoing restoration at the Midland Railway, Butterley)

More wall insulation was installed, further work was carried out on the panels that go behind and above the luggage racks, some ceiling panels were trimmed to make them join the aforementioned panels properly, and when the following picture was taken the gap between the saloon and vestibule ceilings was in the process of being filled in...

The first two light covers were installed...

The door jamb on the hinge side of door no. 3 on the secondman's side of the vehicle was fitted...

... but the jamb on the lock side of the same door put up more of a fight and will require some packing pieces to be made and fitted.

Thanks to Allen Chatwood, John Joyce and Mike Martin for supplying the pictures

With no requirement to run trains during the ongoing closure of Llangollen Railway we are taking full advantage of the opportunity to catch up on maintenance and restoration activities including some of the low-priority jobs that might otherwise have had to wait for the proverbial rainy day - something that can take much longer to arrive than an actual rainy day in Llangollen!

During the fortnight since the previous report, a variety of work has been carried out on both sites (Llangollen and Butterley) by a total of fourteen group members and our vehicles of classes 100, 104, 105, 108, 109 and 127 have benefitted as a result. Further information about the work carried out can be found below.

Work was carried out on the water damage in 50454, with some gentle hand sanding...

...and application of stain to match the surroundings. Varnish will be applied at a later date. A start was also made on sprucing up some of the ceilings including this one in a vestibule...

The fuel supply and return flexible pipes were replaced on the 50454 no. 1 engine.

A start was made on installing the recently-delivered wall panels for the standard class area...

there was further painting of the metal upstands for the first class section...

... and gloss paint was applied to the timber beads that cover the joint between the upstand and the wall panels...

Some studs were manufactured to secure the heater panels to their back boxes and our orange-liveried, orange paint specialist applied a second coat of orange to some electrical trunking lids and conduit components. He was also spotted making innovative use of a line of string that just happened to be there ...

Class 108

The ceiling of the Guard's van in 51933, which had suffered some damage due to water ingress during the winter, was given a good sanding and, because the job was carried out by the orange-livered, orange paint specialist, the Battery Isolation Switch (BIS) cover received a coat of orange as part of the deal!

Class 109 (Wickham)

The no.2 vacuum brake cylinder on 50416 that had been removed for repair at the previous meeting was cleaned inside and out...

...prior to the outside being given a coat of chassis black. The following picture shows the inner and outer cylinders with the piston in the background. Unfortunately the plan to refit the cylinder was thwarted because the replacement bronze bush that had been ordered had failed to arrive in time. The bronze bush goes in the hole in the cylinder so that the piston rod can pass through it and there is a gland to make it airtight. The original bronze bush had become sufficiently worn to cause repeated gland failures.

Additional work was carried out on numerous bits of associated brake gear.

Class 127 vehicle no. 51618 (undergoing bodywork repairs at Llangollen)

A needle gun was used to strip the rear buffer beam and part of the chassis down to bare metal although the job was, unfortunately, cut short due to the failure of the compressed air supply.

Various jumpers, jumper dummies, vacuum dummies etc. were cleaned and painted...

...and then refitted to the vehicle. The following picture was taken when a jumper lid was being fitted and the person concerned was trying to persuade the spring to do what it was meant to do rather than what it wanted to do!...

Some doors were removed, fettled and sanded inside and out...

The new battery box was fitted, given a coat of white gloss inside and the electrical connections were then fastened to the outside of it - something that was more difficult than it should have been due to various other things getting in the way!

The new woodwork in the Guard's van was given a coat of white undercoat and the hole in the ceiling was patched up...

Class 100 trailer car no. 56097 (undergoing restoration at the Midland Railway, Butterley)

More wall supports were installed for the panels that fit above the luggage racks...

... and the edges of some wall panels that had been sanded down to make them fit were given a coat of stain prior to the panels being fitted...

The aforementioned jobs were presumably deemed to be too quiet because the team then went on to trial-fit some door jambs - a job that involved repeated tests to find out whether or not a door would shut properly...

Thanks to Allen Chatwood, Mike Martin and Martin Plumb for supplying the pictures