On Sunday 21/04/24 a shunt was carried out at Pentrefelin in order to extract the Wickham class 109 from the shed so that further elements of the 'M' exam (especially those that required the engines to run) could take place outside. The following picture shows the hybrid class 127/108 and the class 108 during the shunt-a-thon...

...and the Wickham class 109 in the daylight for the first time since mid January...

Information about some of the work that has taken place on our units at Pentrefelin (Llangollen) and Butterley (Midland Railway) since the previous report can be found in the 'Unit-specific work' section below.

Since the previous report, train services have been provided by the class 108 and the hybrid class 127/108, mostly individually but also in multiple on days when a 4-car was required to provide the necessary seating capacity.

...and later at Carrog waiting to depart towards Corwen...

Everything went according to plan except on Saturday 04/05/24 when the class 127 generated a storyline reminiscent of those in the late Reverend Awry's "Thomas the Tank Engine" books. While working the Empty Coaching Stock (ECS) service to Corwen in the morning it surprised its crew by taking an instant disliking to Berwyn Tunnel. Rounding the curve towards the tunnel entrance the emergency brakes were automatically applied and the train stopped with the power car inside the tunnel and the trailer car outside...

It turned out to be a problem with an electro-pneumatic (EP) valve that had caused a sudden loss of the compressed air supply. Once the problem had been fixed the unit was turned around at Glyndyfrdwy from where it returned to Llangollen. It was then sent to Pentrefelin Depot and placed on the 'naughty step' and the class 108 was allowed to play out instead.

The corridor end door was tackled by first of all removing the fixtures and fittings and then giving it a good sanding down where required. The outside panel is aluminium so it was given a coat of etch primer but the previous paint hasn't taken too kindly to that in a few places which is a pity.

Most of the work has been concentrated on the back wall with much cutting, fixing, removing to make alterations etc...

It was decided to rip out the frames that were installed either side of the doors in vestibule one several years ago, the reason being that they are too thick and make the panel sit at an angle that looks odd - proof indeed that the Cravens restoration team is determined to do a quality job!

It turned out to be a struggle to remove the framework so it is a relief that the corresponding framework in vestibule two is fine and does not require attention.

Some vacuum pipes were replaced between the two vehicles after it was discovered that they had become frayed.

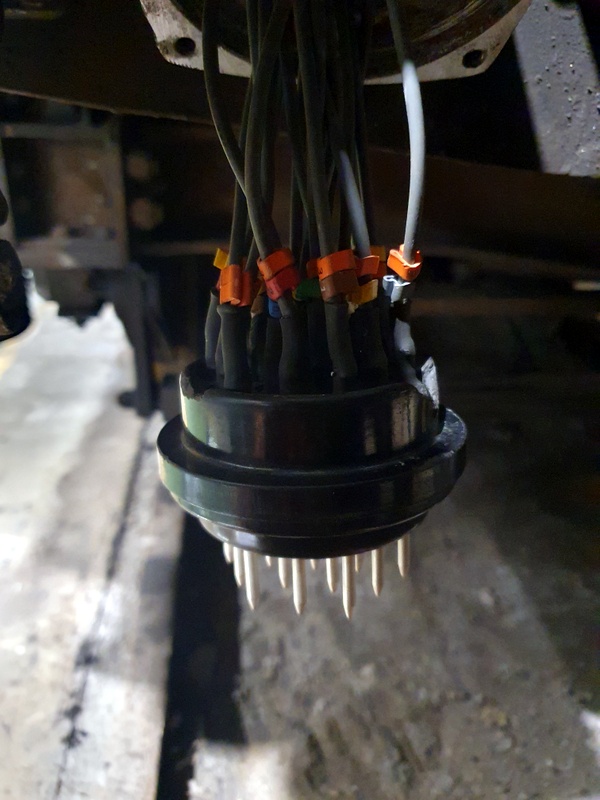

The 'M' exam progressed with the replacement of the pins and wires in some of the jumper cables...

The other end of the replacement wires needed to be terminated in the 'Clapham Junction' terminal box inside the unit...

The system was then tested using these special jumper cables that are connected to a 'home grown' test box designed to monitor and operate the functions that are controlled via the train wires including the throttles, gears, lights and buzzer...

Another job was to recommission the toilet - something that was expected to be a quick and easy job but turned out to have a nasty surprise because the filling of the header tank

resulted in the discovery of a burst pipe. Although we had 'winterised' all of

our railcars in the usual manner, and were under the impression that last winter hadn't been a particularly cold one anyway, we have now discovered a total of three burst pipes. Two

of them were under the sink in the class 108 (as reported in the previous edition of this newsfeed) and this one was above the ceiling in the Wickham's toilet compartment...

It transpired that the cause of the problem was that part of the pipework ran uphill and provided a trap for water even after the system had been drained...

The pipe was replaced with one that runs downhill in the required manner.

The work on the brakegear on 56171's no. 1 bogie was completed, adjusted and given a successful preliminary test. It now awaits a real test run.

Shortly after the failure in traffic on 04/05/24, the four electro-pneumatic (EP) valves that work the throttles were removed, stripped, cleaned, lubricated, refitted and tested in the hope that they will not cause any further problems.

The secondman's door of the trailer car (56223) had been reported as sticking so a small amount was shaved off it and the lock was removed, stripped down, serviced and refitted...

Gloucester class 100 51118/56097 (undergoing restoration at the Midland Railway, Butterley)

The first vestibule on the secondman's side had some framework fitted above the passcom (emergency passenger communication) box and a panel fitted to it. It now awaits the beading...

The door in the second vestibule received the framework and awaits the two panels...

Work has also progressed with the fitting of more window frames.

Thanks to Allen Chatwood, John Joyce, Mike Martin, Martin Plumb and Craig Robertson for supplying the pictures that were used in this edition.