Information about some of the work that has taken place on our units at Pentrefelin (Llangollen) and Butterley (Midland Railway) since the previous report can be found in the 'Unit-specific work' section below.

The group recently acquired a new item of rolling stock in the shape of this trolley that makes it much easier to transport tools, oils, coolant etc. up the yard at Pentrefelin...

I wonder what the driver training will entail? :-)

A start was made on painting the refurbished buffers that were recently returned to us and, at the time of the following photograph, the shank of one of the three had been painted red...

If there is such a thing as stealth trainspotting it is clearly possible to practise it while working on/under/between our railcars at Pentrefelin Depot...

The class 108 has been very busy since the previous report because it has done a number of Berwyn Shuttle services, some 'A' timetable Corwen services, and it also got to play out with various other locomotives during the Branch Line Gala that took place on 12-14 April. The following picture shows it at Berwyn Station with a Berwyn Shuttle service on Saturday 30/03/24...

The following pictures show it passing Pentrefelin Depot with a returning Berwyn Shuttle service on Sunday 24/03/24...

The following pictures were all taken on the Friday of the Branch Line Gala and they show the unit rubbing shoulders with 0-6-0 Pannier Tank 7754 at Llangollen Station...

...and with Austerity 0-6-0ST "Robert" masquerading as J94 no. 68067 at Glyndyfrdwy Station...

On the Friday and Saturday of the gala the class 108 returned to the depot after finishing its daytime services...

...and later ventured out again to provide some evening services to/from Glyndyfrdwy...

The rear wall now has all the timber pieces needed for the wall panels and is nearly full of insulation...

The last panel of plywood for the floor at the rear had to be removed because it had been fitted on a slope, the same as the rest of the floor, but needed to be flat so that the bottom sliding door rail could fasten to it. Its removal provided an opportunity to take some measurements and make a template for the heater ducting...

At the front of the unit the timber ceiling support over the driver's door was fitted and the metal cover attached to it...

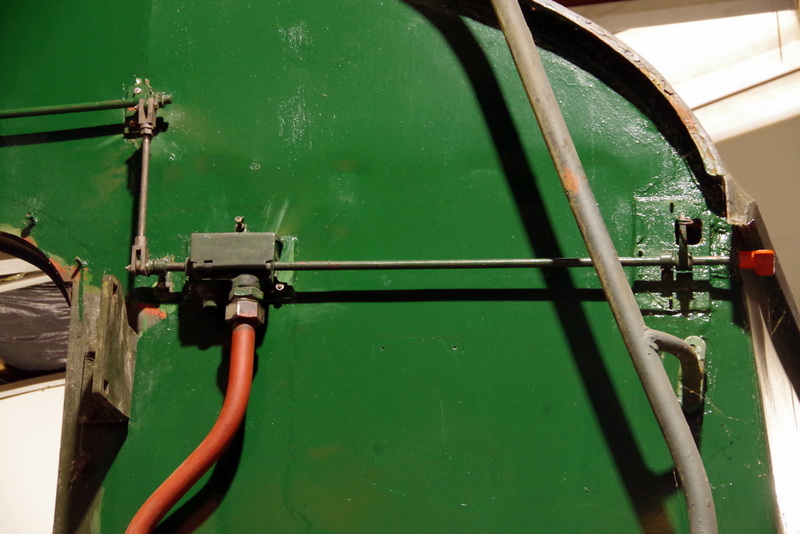

On the outside of the vehicle the external passenger communication (passcom) system was installed and the associated chain was installed along the driver's side. The 'passcom' is the system that is used by passengers in an emergency and it works by making a brake application.

Class 108 51933/54504

During the weekend of 6/7 April the unit was given an 'A' exam, most of which went according to plan although there were one or two things that required extra attention including this sliding quarterlight in the first class section...

...and the plumbing in the toilet compartment...

Despite our efforts to 'winterise' the fleet, water had found some places in which to hide in this pipework with the result that a couple of pipes under the sink had burst. They posed a bit of a challenge to sort out but eventually a new pipe section was produced in plastic to replace a couple of copper sections.

The 'M' exam progressed with a number of jobs including a detailed examination of the final drives. The following picture shows the innards of the no.2 final drive...

The device that has "LL20" written on it can be ignored because it is a torch (an essential item in the gloomy confines of the bogie!). To the left of it can be seen the selector fork which, when driven sideways by a piston under the influence of air pressure, moves a sliding dog and connects the drive from the gearbox with either the bevel gear on the left or the one on the right. Those gears are in constant mesh with a larger gear wheel, part of which can just be seen behind the bevel gear on the left, so the choice of the left or right bevel gear determines the rotational direction of that larger gear wheel and hence the direction in which the vehicle will travel.

As shown in the picture the sliding dog is in the central (neutral) position so neither direction is selected.

Work also progressed on the cleaning/servicing/painting of the various items of brakegear that have been removed...

The newly stained and varnished beading was fitted in the first class section...

In the middle compartment some more window frames were fitted and the horizontal beading was fitted thereby allowing the vertical beading to be cut and drilled. The following picture shows the horizontal beading fitted and the vertical beading in the process of fitting...

Some electrical work was also carried out, both in terms of wiring the jumpers on the front of the vehicle and determining the positions of the required junction boxes and conduit.

Thanks to Allen Chatwood, Andy Lowe, Mike Martin and John Joyce for supplying the pictures that were used in this edition.