Although we have not been running any trains during the winter closed season we occasionally have to shunt our railcars into different positions in order to facilitate some of the maintenance and restoration activities. That can produce some unusual combinations such as the following with the class 108 power car coupled to the class 104 and the class 108 trailer car coupled to the Wickham class 109...

A summary of the work that has taken place since the previous report can be found in the Unit-specific work section below. The majority of it has been an "all hands to the pumps" effort to refurnish the class 108 but restoration work has also continued on the Cravens class 105 trailer car at Pentrefelin (Llangollen) and on the Gloucester class 100 at Butterley.

A luggage rack backing panel which had been removed last year to assist with the threading of the pass com chain was cut into 2 pieces and the larger section re-fitted...

At the back of the unit an experiment was carried out with the curved timber that will carry the sliding door gear for the connecting door and it was discovered that it will need 'a bit of fettling'...

Prior to the delivery of the reupholstered seat backs, bases and armrests, some more improvements were carried out to the insides of the vehicles. That included the staining and/or varnishing of some of the wooden panels including the window surrounds and sliding doors..

...and the replacement of two wall panels in the first class section that had been previously damaged and not-very-tidily repaired. The replacement panels are printed vinyl on 'Dibond' of the type that we are using on the Gloucester class 100 at Butterley and, as luck would have it, the colour match is quite good...

Almost as soon as the reupholstered seat backs, bases and armrests were delivered several teams of people set about fastening them to the frames...

At first sight it will look as though the person on the left in the above picture was simply standing and watching the other one doing the work. The two of them were, however, working as a team using a hastily developed, yet highly successful technique in which one of them used two pieces of wood as levers to press the seat back firmly into the correct part of the metal framework while the other inserted the screws from underneath. The following picture shows the same technique being deployed in the power car...

The following pictures show the (almost) finished result with the grey moquette in the first class section of the trailer car...

....the blue/green moquette in the standard class section of the trailer car...

...and the purple moquette in the standard class power car...

Not forgetting the driver, secondman and guard...

The driver's side corner of the cab of 51933 is now looking much healthier than it did thanks to the recent bodywork repairs and painting...

Following the recent discovery that a corridor tread plate for a class 104 does not fit a class 108 we have now acquired one of the correct size. The following picture shows it next to the one that it will replace (and one that has clearly seen better days!)...

The heating ducting was fitted with new fixing brackets, which were then secured to the wall and floor on the 2nd man side of the first class compartment.

The 3” x 2” timbers that fit into a recess by the cab windscreens were cut, drilled, then the metal corner stanchion with the recess in was drilled and tapped. The timber was squared up to the window glass before fitting.

Thanks to Allen Chatwood, John Joyce and Mike Martin for supplying the pictures.

I would like to start by wishing our readers a Happy New Year!

December was a busy period for the group with three working meetings at Llangollen and one at Butterley. The most recent meeting at Llangollen was the so-called "Cold turkey" meeting that traditionally takes place between Christmas and New Year and provides members with an opportunity to regain a sense of normality in between family festivities etc.

Whilst most of the work at the Pentrefelin Depot, Llangollen, took place inside the shed (no bad thing in view of the predominantly wet weather!) some members of the group were let loose with a van to make some deliveries and collections. Amongst other things they acquired a shiny, new paint cupboard, some second-hand ("one careful owner, never rallied nor raced"?) gangway connections and they dispatched three poorly buffers for repair.

We also received a couple of new corridor tread plates although Santa made a mistake because they are of size=104 which is spot-on for the class 104 and some of our other vehicles but too big for the class 108 which was the intended recipient. Fortunately they are compatible with the Cravens class 105 trailer car which is also in need of some so there will be no need to return them to the North Pole. We will, however, need to look elsewhere for some for the class 108.

A summary of the work that took place on specific railcars since the previous report can be found under 'Unit-specific work' below.

...some window beads below the sliding windows...

...and some ceiling beading that had been drilled and painted as a homework project...

The class 108, both vehicles of which are currently inside the shed at Pentrefelin, definitely won the lion's share of the work that was carried out during the period in question.

Work continued with the deep clean, the idea being to clean the things that have been exposed and made easier to access following the removal of the seat backs and cushions. The job involves lots of "elbow grease" and cleaning potions of various descriptions. If only the seats were more comfortable! :-)

There was plenty of grime to tackle. For example, the following picture shows the ducting of a heater air intake, the top part of which has been given the treatment and the rest still to be dealt with...

An investigation into some paint bubbles and corrosion on the driver's side of the cab of 51933 resulted in the discovery of a lot of corrosion that had evidence of a previous repair with filler. The area was repaired by cutting back to bare metal and welding a patch...

Some defects on the front of 54504 were also repaired, with a few small areas patched up with paint and filler, and the yellow panel on the front was given another coat of gloss paint.

The marker lights on 51933 also got attention, in that the glass that hasn't been fastened in since the unit came from Swanage is now fastened in, and both markers were cleaned out prior to primer and white paint being applied.

Although the star of the following picture was meant to be the new, hi-vis paint cupboard, it also shows a marker light on the front of 51933 looking resplendent after being given the treatment. Hopefully a few more of the photons will now find their way out to illuminate the outside world!

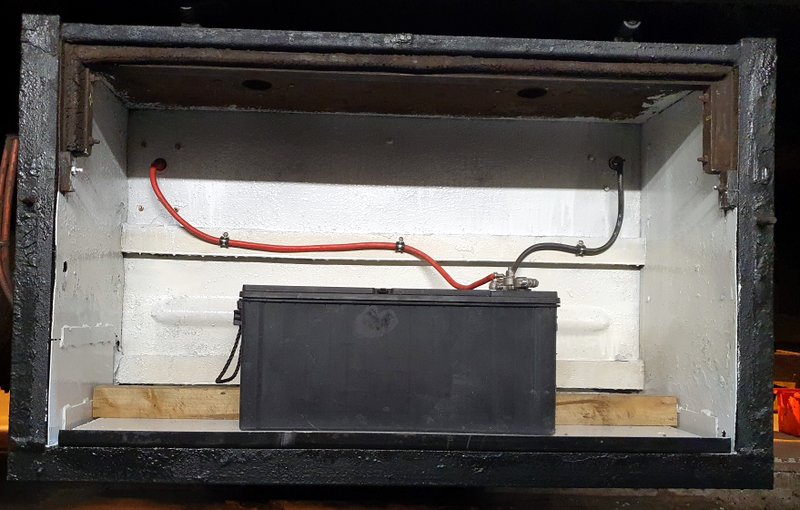

The battery box on the driver's side of 54504 received a welded repair prior to reconstruction, painting, and the reinstallation of the battery...

Some of the woodwork in the first class area of 54504 was given a light sanding prior to staining and varnishing

A considerable amount of work was associated with the corridor connection of 54504. That included the production of a new panel for the gangway door, the freeing of a seized pivot and the partial fitting of the corridor canvas which now awaits the acquisition of some tread plates following the discovery that they are of a different shape and size to the class 104 ones that were purchased.

Two sets of window frames were produced and are now awaiting staining and varnishing as a homework project.

The floor panels between the second vestibule and rear compartment were sanded to eliminate a step in the joint between the recently-laid panels.

Thanks to Allen Chatwood, John Joyce, Mike Martin, Graham Parkin and Martin Plumb for supplying the pictures.