Having just about got into the swing of our winter maintenance season, thoughts are turning to the next running season which commences in less than four weeks' time on Saturday 19 February. The time really has flown so, according to the well-known phrase, we must have been enjoying ourselves!

Most of the work that has taken place on our railcars since the previous report is described in the 'Unit-specific work' section below. There has, however, also been some work on components destined for different units such as the painting of these fire panel covers and finger pull boards that had come back from grit blasting. The fire panels are destined for (class 108) 51933 and (class 127) 51618, and the finger pull boards, that were given a protective coat of gloss paint on the side that will be hidden when they are reinstalled, are destined for the class 127...

Various "housekeeping" jobs were also tackled including the cleaning of the gutters on the side of the shed and our mess coach, electrical work in both of the aforementioned, the dismantling of some batteries for recycling, the tidying of our wood store, and the sheeting over of the recently-acquired wheelsets in order to protect them from the weather...

The hybrid class 104/108 and the class 108 spent some time sunning themselves on a different siding last weekend so that the Wickham unit could be pulled out of the shed (by the class 104 power car no. 50528) for the continuation of its 'B' exam...

50454 was given a new set of batteries to replace the life-expired ones.

Work continued with the fitting of the ceiling beads in the 1st class compartment...

... and the fitting of a frame to a large window in the centre compartment...

The mounting brackets for the sliding door at the end of the unit were removed so that they can be straightened out in readiness for refitting...

The corridor faceplate was tackled with scrapers and a wire brush...

The 'wedge' that locates the corridor faceplate against its partner was removed for welding up and the handle that clamps the two together was cleaned up...

The newly painted covers for the relay box, lighting control box and fusebox on 51933 and the dynamo control box on 54504 were installed...

A start was made on the 'C' exam by topping up the batteries, topping up oils, checking the lights, changing the engine air filters etc. The previous report included a picture of our new custom-made tool for removing air filter bowls but left readers in suspense as to how it is used. All can now be revealed because here it is being used to unfasten (or fasten?) the wing nuts with better reach and leverage than a typical arm and fingers...

The remaining 'B' exam jobs were steam cleaning, and the checking of the doors. The former turned out to be straightforward (apart from the operator getting wet) but the latter resulted in cries of "The doors, the doors" (cf "The Bells, The Bells") of a type that normally emanate only from those involved in the restoration of the class 127 with its seemingly infinite number of doors. In the case of the Wickham, the secondman's door of 50416 needed lots of sanding in order to make it behave correctly...

... and one of the guard's inward-opening doors, which was dragging on the floor, also needed a good dose of sanding as well as the lifting of the treadplate for attention...

Wiring was installed in the new battery boxes to make them compatible with the use of leisure batteries...

The task of servicing the many doors and their components continued. Each of the doors is scraped/sanded/primed...

... and the various components are dismantled, cleaned, reassembled and reinstalled. The following picture shows some 'scissors' (the spring associated with the droplight) that have been refitted to a door after servicing...

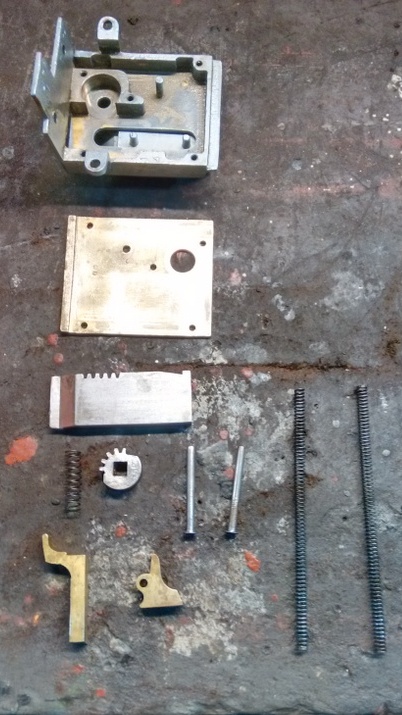

... and the following one shows a lock that has been reduced to a kit of parts and cleaned in readiness for reassembly...

Much of the above work at Pentrefelin was monitored by the self-appointed depot foreman...

The five members of the group who were present at the time chose the shade of green, from five supplied samples, that best matched the colour of the existing wall panels so that the new panels can be ordered. They were unanimous in their decision so it should be a good match!

Various other jobs included removing stains, applying stain and, rather frustratingly, having to remove, sand, and refit luggage rack backing panels that had already been fitted. They are thought to have suffered from the same problem as the doors on the Wickham - namely the damp swelling the wood.

Thanks to Allen Chatwood, John Joyce, Mike Martin and Martin Plumb for supplying the pictures.