Most aspects of the group's activities continue to be affected by the coronavirus-related regulations and their knock-on effects but one that has actually benefitted has been the "homework". This relates to items of equipment that are constructed/restored/repaired etc. by some of our members at their homes and, because they are mostly longer-term projects for which there is no immediate requirement, they tend to form a queue waiting for the person's enthusiasm to be engaged one "rainy day". However, the desire to spend time in sheds and garages has increased during periods of coronavirus lockdowns, travel restrictions etc. - possibly because tinkering with DMU components is rather more rewarding than typical domestic duties - and, as a result, there has been a corresponding decrease in the number of items in the queues!

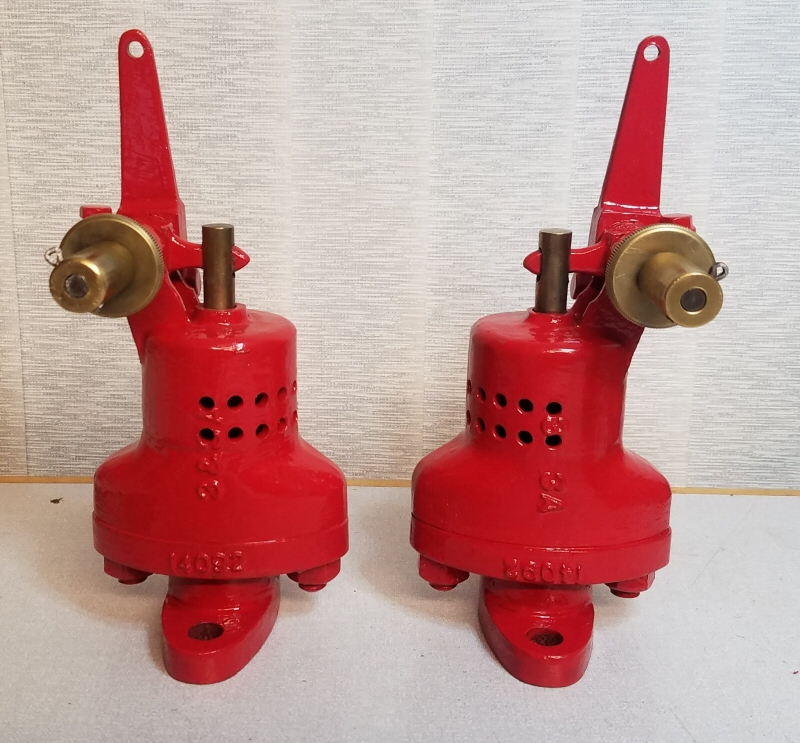

One such project has been the restoration of two passcom valves for the Class 100 'Gloucester' trailer. A passcom (short for passenger communication) valve is used to admit air into the train's brake pipe if/when a passenger pulls the emergency communication cord.

This is what one of the valves looked like to begin with...

With its sibling in the background, nervously awaiting the same treatment, the valve was reduced to a kit of parts...

... and then restoration began ...

Finally the finished products - both valves looking as good as new and ready for installation and commissioning when the time comes...

Also for the class 100 we were delighted to receive a delivery of some cab side panels and door header panels that had been sent away to be powder coated...

Further work has been carried out on the Gloucester trailer vehicle at the Midland Railway, Butterley as can be seen below.

The gear controller was wired in...

and more insulation was fitted in the cab...