Since the previous report we have provided 'A' timetable services on Tuesdays - Fridays using the class 108 and the Wickham class 109 either solo or in multiple in accordance with the forecast passenger numbers. The class 108 also worked last Sunday when it had some company in the shape of a class 08 shunter that provided the Berwyn Shuttle services as well as opportunities for members of the public to be a 'Driver for a Fiver' at Llangollen Station.

The above period included 'Torrid Tuesday' (19 July) when temperatures exceeded a sweltering thirty degrees Celsius in the shade and the Wickham (class 109) and the class 108 operated as a 4-car unit. It must be some considerable time since any of our DMUs operated in, or even experienced, such temperatures!

The following timeless scene of the green 4-car DMU arriving at Carrog was taken by Richard Walliker on Wednesday 13 July...

The no. 2 engine of the class 108 developed a strange fault by occasionally shutting down for no apparent reason. It was an unusually user-friendly fault, though, because it only ever happened when the unit was at either Llangollen or Carrog station waiting to start its next journey and, instead of it being necessary for the driver to intervene in some way by, for example, adding extra coolant, the engine was happy to restart each time and then behaved for the whole journey! Not to be outdone, the no. 1 engine of the Wickham class 109 developed the seemingly opposite fault by occasionally refusing to stop! Further information about the work carried out to diagnose and repair those faults can be found in the unit-specific work sections below.

The construction of the second tool cupboard is progressing nicely...

It may soon be time to find a local dignitary to conduct the opening ceremony by cutting a ribbon with an angle grinder :-)

Information about the work that was carried out on specific railcars can be found in the unit-specific work sections below.

This class 104 DMCL (Driving Motor Composite Lavatory) vehicle has not been in the news for a while because it is currently orphaned and in need of bodywork repairs. Its usual partner (no. 50454) now forms half of the hybrid set with class 108 trailer no. 56223.

A start has been made on the secondman's side by digging out the paint and filler that had cracked and then sanding the whole lot, applying primer and undercoat. Some Sikaflex was also applied as sealant around a couple of windows.

The annual 'A' exam of the trailer car (56223) was completed. There was nothing much of note but the arm rests in the first class section were found to be loose so some effort went into securing them.

The vehicle went for another trip to the suburban platform/staging so that gloss paint could be applied to the secondman's side. There are no prizes for spotting that it's the wrong colour but it will, at least, protect the bodywork until the proper paint job can be carried out...

Investigations into possible causes of the occasional unexpected shutdowns of the no. 2 engine (see 'Out and About' above) revealed a loose engine harness plug so it was thought that that might be to blame. However, the engine did another defiant shutdown the day after the harness plug was tightened so the jury may still be out for that one.

The discovery of loose armrests in the first class section of the hybrid set led to the ones in the trailer car of this class 108 (54504) being tightened as well.

The appearance of the outside of the unit was improved somewhat with the addition of some chassis black paint in its nether regions and some yellow on the axlebox covers.

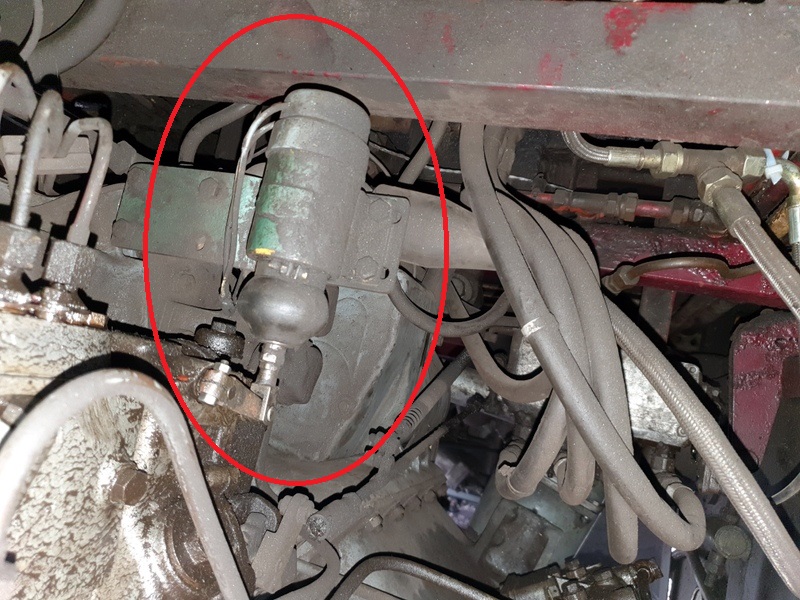

Investigations into the Wickham's 'no shutdown' problem turned out to be more conclusive than those for the class 108's 'shutdown' problem because it was discovered that the stop arm that is operated by the stop solenoid was broken...

In view of the nature of the fault it was difficult to work out how the stop arm managed to work some of the time but it did! It was replaced with a spare from the store and it was noted that a fractured stop arm is much easier to deal with than a fractured crankshaft! :-) Highlighted in the following picture are the engine stop solenoid and the stop arm on the fuel pump...

The Wickham was given a Fuel Point(FP) exam that was largely uneventful apart from the discovery that the fire bell in the cab of 50416 didn't work. The solenoid coil was open circuit so a spare bell was raided for components and the problem was cured...

The windows and luggage racks were given a good dose of cleaning...

Some roof patches were cut out, formed as necessary, and mostly welded into place...

After the new steel has been primed the next job will be to refit the gutter. Further down the line the guard's door will need to be refitted but that will have to wait until there is something to fit it to.

More beading was fitted to the ceiling in the centre compartment, including a couple of half beads which fit up to a light fitting...

The second ceiling panel for the cab was measured, cut and fitted...

Thanks to Allen Chatwood, John Joyce and Richard Walliker for the pictures.

The Wickham class 109 provided the 'A' timetable services last week (Tuesday - Friday). A few minor faults were noted and all of them were attended to last weekend as described in the Class 109 Unit-specific work section below.

Flushed with the success of last month's attempt to optically convert a 2-car class 108 to a single car one with the aid of the mirror in the Carrog cafe, the same driver tried a repeat with the class 109 this month. There was an unexpected side effect this time because he managed to clone one of the customers too! ...

A shunt-a-thon to move the Cravens trailer to the staging as a convenient place to paint its "river side" resulted in Pentrefelin looking like a DMU depot...

Even more so with the aid of a makeshift mirror...

Information about the work that was carried out on specific railcars can be found in the unit-specific work sections below.

Some areas of paintwork that appeared to have suddenly 'let go' recently on the secondman's side were tackled over the weekend. The plan was initially simply to protect the affected areas pending 'proper' bodywork at some future date but the job rather rapidly "developed" when quite a lot of areas were found to be hiding significant amounts of corrosion. It turned out not to be the best weekend for the job because, even though the work site started off in shade...

...it wasn't long before the unrelenting sunshine and high temperatures resulted in both the paint and the painter drying out (or going off?) rather rapidly! Despite that he managed to sand and paint the whole of the secondman's side...

...and, as a, "While the paint's out..." follow-up he also attended to the front corner of the cab on the driver's side which appeared to have been damaged by tree sap while the vehicle spent several years tucked away in the siding nearest the canal.

Before...

During...

After...

Finally some corroded areas on the back of the vehicle were given the treatment too.

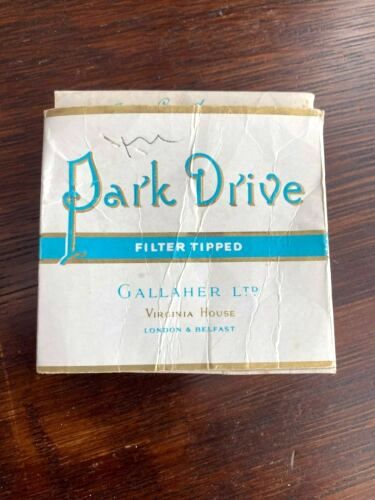

Two door locks required some attention to improve their operation. The secondman's door on the trailer car (56171) needed the striker plate shimming and it turned out that it was previously packed out with a cigarette packet...!

I never fail to be amused when the police officers on television crime dramas (American ones in particular) are despondent about their one-and-only piece of flimsy evidence until one of them has the idea of submitting the blurred photograph of a vehicle 100 yards away, for example, to "the guys in the lab" who rapidly perform miracles by not only producing a clear image of the vehicle's registration plate but, after waiting the requisite amount of time for the officers to show their admiration, follow it up with the piece de resistance in the shape of a crystal-clear image of the receipt from a local hardware store that just happened to be on the vehicle's dashboard at the time and could be "pulled out of the image"! Well, I got as far as convincing myself that the cigarette packet that was used as a makeshift shim was similar to this one...

...but soon after that my detective work "ran into the sand". If only I had access to "the guys in the lab" they could, no doubt, tell me where the cigarettes were bought, when and by whom, and, after giving me chance to look impressed, go on to tell me when and where the used packet was deployed as a shim!

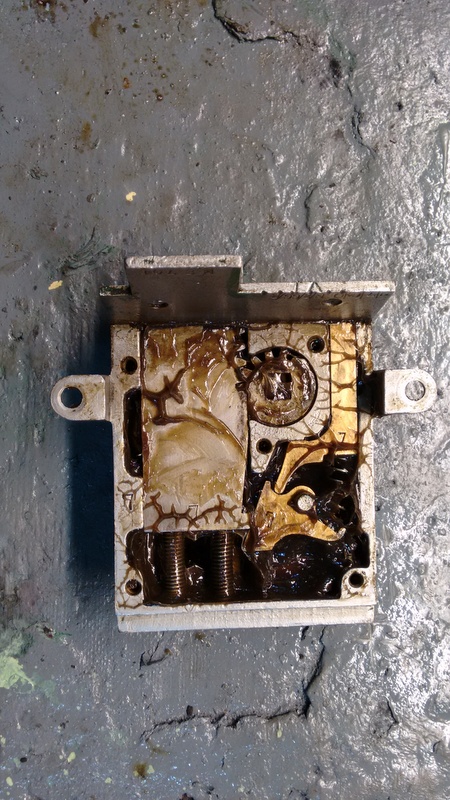

Another door lock (this time on the power car 50416) was serviced by dismantling it, removing the old, dried-up grease etc., cleaning all the parts, reassembling and adding new grease. Part way through the operation it was realised that 'before' and 'after' pictures would have been useful but it was, unfortunately, already too late for the former so here is the latter prior to the cover being put back on...

Investigations were also carried out into a problem with the horn on the trailer car (56171), it having been noted that the low tone was not as loud as the high one. That turned into a project in its own right, firstly because the the horn valve is under the driver's desk, the dismantling of which turned out to be a bit of a Chinese puzzle, secondly because the need to isolate the air supply to the trailer car at one stage revealed that the valves between the two vehicles had seized, and thirdly because the feed valve, which is associated with the vacuum brake and also resides under the desk, failed while the horn repair was being carried out even though it had not been disturbed in any way! Although it was unfortunate that the job list was rapidly expanding it was also rather fortuitous that the feed valve failed while the unit was at the depot (instead of causing a failure while out in service) and while the front of the desk was already open! Another amazing coincidence was that a replacement valve had been delivered that very day after being refurbished as a homework project.

The problem with the horn was cured by replacing the rubber seals in the valve, and the shut-off valves between the vehicles were given a good service so that they now work properly again too.

The feed valve was replaced with the refurbished one (the white item in the following picture) - a tricky job due to its location under the desk: there is only room for one person to gain access and yet the job occasionally requires three hands!

The faulty feed valve was stripped, overhauled and put into the store as a working spare. It turned out that it had a split in a diaphragm...

For the benefit of 'new readers', the feed valve allows the exhausters to create a high vacuum (typically 27-28" Hg) in the release reservoirs whilst restricting the vacuum in the train pipe to a lower working maximum of 21" Hg. A more detailed explanation of that and other aspects of the quick-release vacuum brake system that is used on railcars can be found at https://railcar.co.uk/technology/brakes.

Whilst on the subject of the quick-release vacuum brake system, the small brass plaque on the desk of 50416 proclaiming the fitment of Gresham and Cravens' "AIV" system has had its matching partner installed in 56171. Our chairman acquired it via ebay several years ago and had "finally dug it out, cleaned it, lacquered it and brought it back"...

Thanks to John Joyce, Mike Martin and Martin Plumb for supplying the pictures.

After running with the class 108 as a 4-car DMU on the 'A' timetable service last Tuesday-Friday, the Wickham class 109 went solo for its role as the railcar in the Classic Transport event which was the first major event to have taken place at Llangollen Railway in three years.

The 'centre of the universe' was the events field next to Glyndyfrdwy Station where there were lots of vintage vehicles and other items on display. Passengers travelling to/from the event had a choice of three trains (the DMU, a Diesel-hauled service and a Steam-hauled service) as well as some vintage buses which took people to look at the ongoing development of the new station at Corwen. There was plenty of variety for the train crews too with unusual moves including trains that turned round at Glyndyfrdwy and returned to Llangollen or Carrog as appropriate.

The following pictures were all taken on Saturday 2nd July

The turn-arounds at Glyndyfrdwy provided some rare opportunities to find/use it on the destination blinds...

After this arrival of a train from Llangollen hauled by class 31 31271...

...the Wickham set off back to Carrog...

Finally it was photographed at Llangollen Station after the close of play and prior to making its way back to the depot...

Thanks to Mike Martin for the pictures.