Information about the services that our railcars have provided can be found under 'Out and About' below and work that has taken place on the railcars at Llangollen and Butterley can be found under 'Unit-specific work' below.

During the weekend of 9/10 September a shunt was carried out to move class 127 vehicle no. 51618 to the daylight end of the shed in readiness for a forthcoming test/gauging trip to Corwen (see below). The vehicle has been undergoing extensive bodywork repairs since it was taken out of traffic at the end of October 2019 so we are delighted to be bringing that work to a close and hope that the class 127 will be the star of the Railcar Gala on 7-8 October.

The shunt resulted in the Cravens vehicle 56456 making its way to the back of the shed and the Derby class 108 trailer no. 56223 being sandwiched between it and the class 127.

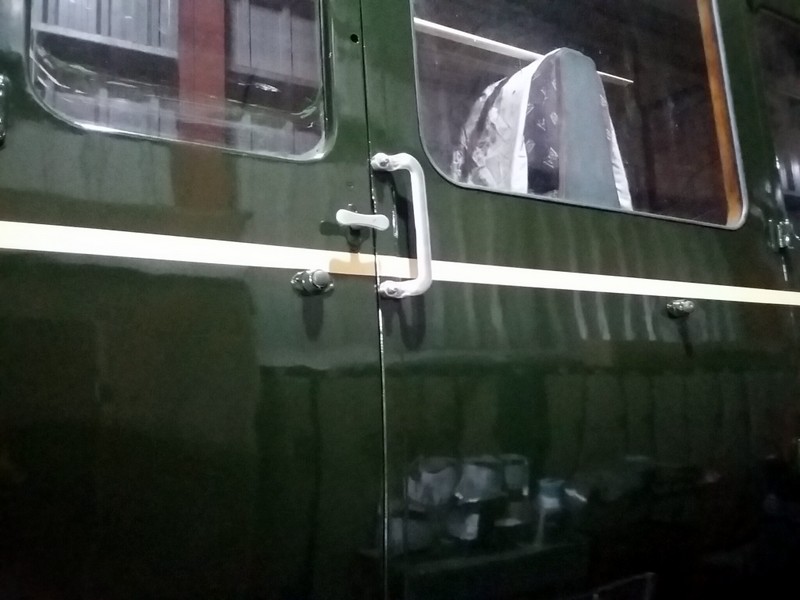

By this stage the class 127, which was surely looking almost like it did when it emerged brand new from Derby Works in 1959, had been lined out on the secondman's side but the lining on the driver's side had still to be done...

It is seen here showing off its glossy finish...

The highlight of the period was Monday 18 September when the newly-restored class 127 vehicle no. 51618 made a successful test/gauging run to Corwen accompanied by the class 104. That was the class 127's first trip on the main line since October 2019 and, because it is several feet longer than our other DMU vehicles, it was necessary for it to sample both platforms at the new Corwen station in order to check the clearances. It and the station both passed with flying colours!

Since the previous report we have run a number of Timetable 'A' scheduled services mostly with the 4-car class 108+109 but occasionally with the 2-car class 108, and some special charters with the class 108.

The cylinder head on the 50454 no. 1 engine was reassembled and the engine now runs properly once again...

There is, however, an outstanding problem because it has since been discovered that the starter motor sometimes decides that it doesn't want to start the engine. Astute readers may remember that this began as a starter motor problem and a faulty motor was replaced prior to the discovery that the engine had seized. Further investigation will take place next weekend and we hope that it will turn out to be something simple (e.g. a bad electrical connection) given that the class 104 will be required to play its part at the forthcoming Railcar Gala.

Class 127 vehicle no. 51618 (undergoing bodywork repairs at Llangollen)

The finishing touches of the bodywork restoration saw the application of the lining, number, the British Railways emblem and rechromed grab handles on the secondman's side...

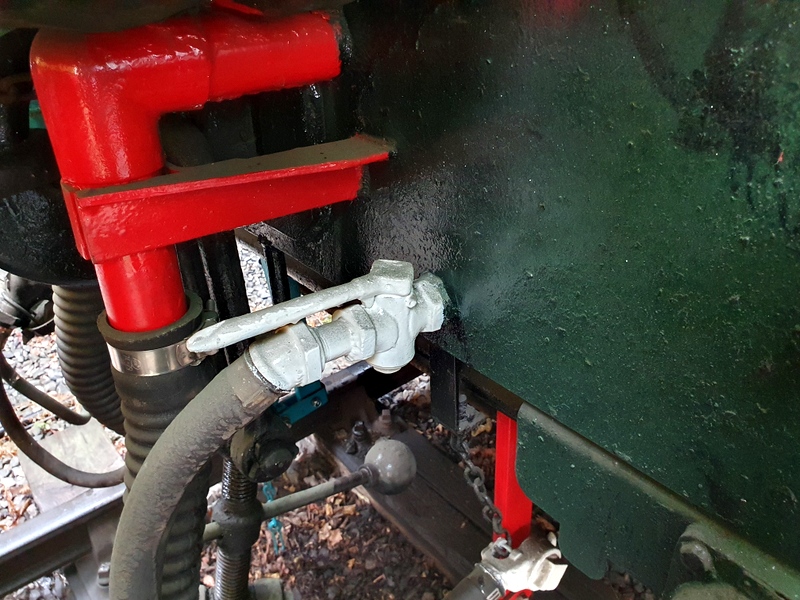

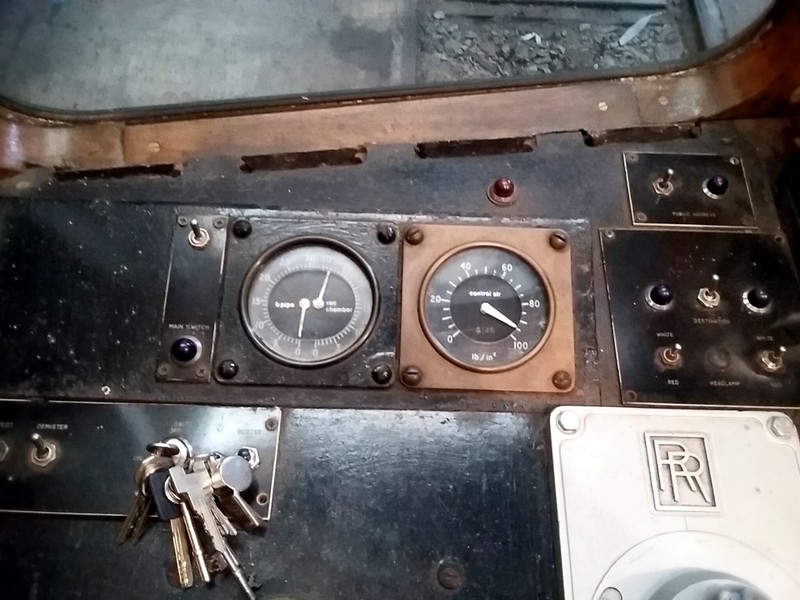

The vehicle was then subjected to a thorough examination in readiness for it to reenter traffic. It awoke from its slumbers quite readily and the problems that were encountered were mostly relatively minor electrical ones - minor in the sense that they didn't "stop the job" even though the diagnosis and repair may not be minor. Unfortunately, though, the inability to create compressed air was a show stopper especially when the cause was identified as a corroded pipe in a particularly inaccessible area behind the bufferbeam. The following picture shows the white-painted air pipe on the outside of the vehicle and the corroded section was near to where it emerged in the gloom at the other side of the buffer beam...

As luck would have it, a nut on an elbow connector not far from the 'scene of the crime' eventually came undone even though it probably hadn't been disturbed since the unit was built in 1959. Lots of hammering, grinding and collapsing of the pipe then saw the pipe break free, albeit with a hole somewhat larger than the one that was there to begin with. We are very grateful to our colleagues in the Carriage & Wagon Department who were able to supply a suitable piece of pipe and the dies to cut the threads. The following picture shows the pipe that was removed and the new one that was constructed...

After the replacement pipe had been installed there was no problem creating and maintaining the required amount of control air pressure...

Thanks to Adam Boddy, John Joyce, Mike Martin and Graham Parkin for supplying the pictures and video.

Information about the services that our railcars have provided can be found under 'Out and About' below and work that has taken place on the railcars at Llangollen and Butterley can be found under 'Unit-specific work' below.

While we were carrying out 'A' examinations on classes 108 and 109 at Pentrefelin on Saturday 26 August, class 25 D7659 provided an excuse for a break when it came to collect the suburban coaches prior to playing its part in the Steam/Diesel B-timetable service that day...

The locomotive was later spotted passing the depot with the 14.35 Llangollen to Corwen service...

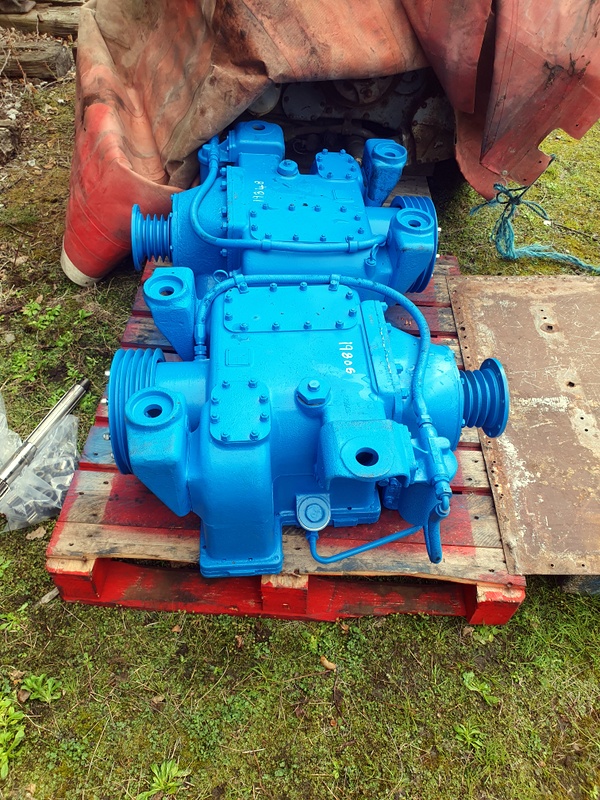

Two gearboxes that had been sent away for repair/refurbishment were returned to us...

One of those gearboxes was the one that was recently removed from the no. 2 transmission on the Wickham class 109 after it started to make a pulsing, whining noise particularly in second gear. To our surprise, some of the faulty components were returned to us as exhibits A, B, C etc. ...

Although some of the wear is readily apparent, it will be left as an "exercise for the student" to work out what those components are and how they fitted together. Some useful clues can be found on the the railcar.co.uk web site: https://railcar.co.uk/technology/gearboxes/ and https://railcar.co.uk/technology/gearboxes/r14

Since the previous report we have operated ten A-timetable railcar services. On each of those occasions we were asked to provide a 4-car DMU so the Wickham class 109 + Class 108 turned out for seven of them and the class 108 + class 104 combination worked the other three. The class 104 ran with one engine isolated due to the recently-discovered problem of water finding its way into one of the cylinders but with five engines per 4-car unit there was no shortage of power!

The following pictures show the 4-car class 108+109 at Corwen and Llangollen respectively on Wednesday 30 August...

Once the 'A' exams had been completed on classes 108 and 109 on Saturday 26th August, a start was made on dismantling the cylinder head of the faulty no. 1 engine on 50454. All seemed to be going well until it came to removing the head at which stage one stud put up a serious fight and didn't want to let the head part company from the block. Various combinations of people set to with chisels, packing, hammers, bars, and presumably a sprinkling of non-approved words...

Several hours later...

The problem didn't seem to be the usual culprit of carbon on a stud and yet, by the close of play, the head would only come off the block by about 1/2" so it was decided to let it "fight another day".

The team regrouped the next morning and, having concluded that yesterday's technique had been working, albeit very slowly, decided to make more use of it in a lather/rinse/repeat manner until they eventually got the better of the errant stud (which suffered some minor damage) by mid afternoon.

The above picture shows the cylinder head with its four ports (two inlet, two exhaust), two of which are shared by two of the cylinders. The port on the left-hand side nearest the camera is a coolant port. With the head off it could be seen that the no. 2 piston had a 'tide mark'; there were no tell-tale signs of cracks in the head but a dark patch on the top of the block suggested that the head gasket had blown to a waterway from that cylinder.

By the close of play on the Sunday the head had been cleaned up and a suitable gasket fitted...

...and the mound of components that had been removed from the cylinder head had been cleaned up...

The damaged stud will need attention from a die nut before final assembly on a future occasion but, in the meantime, sufficient components were reassembled to allow the class 104 to be used if necessary.

Work progressed with the fitting of rubber window stops, the little aluminium beads for the vestibules on the driver's side, and the vestibules also received their top coat of paint...

Some of the timber bead that goes between the floor and the metal upstand was cut to length using a couple of the new heating vents in position to give the correct size...

The timber bead was then taken away to be painted as a homework project.

The unit was given a mileage-based 'A' exam on Saturday 26/08/23.

The unit was given a mileage-based 'A' exam on Saturday 26/08/23.

A faulty engine light on 50416 that had been reported by drivers recently was fixed by cleaning out and refitting the 'Niphan' plug that connects to a socket on the engine...

Class 127 vehicle no. 51618 (undergoing bodywork repairs at Llangollen)

The handrails were cleaned and painted along with the exhaust brackets and a start was made on painting the lining...

This project has become almost a mirror image of the Cravens restoration project at Llangollen, with similar jobs being tackled by a group that comprises a subset of the same people. For example, beading is being installed around the wall panels etc. in both vehicles.

...and the other half was stripped in sections, cleaned, and reassembled so that it will be ready to fit at the next meeting.

The rear compartment was tidied in readiness for the raising of the floor by 3.5mm...

Thanks to Allen Chatwood, John Joyce, Graham Parkin and Martin Plumb for supplying the pictures.