We now find ourselves at the height of the running and holiday seasons when the majority of our effort is focussed on operating trains and ensuring that they are fit to operate - in terms of their mechanical and electrical functionality and also their cleanliness inside and out.

The following pictures were taken during a recent 'all hands to the pumps' cleaning session...

While doing such jobs it is important to look especially busy whenever trains pass by on the main line...

With the hoses already out, the opportunity was taken to fill the toilet header tanks as well, if only until a 'back of the envelope' calculation revealed that it would be much quicker to use the hoses at Llangollen Station. It can take a while for a tank to fill so conscientious volunteers might find other sundry jobs to do in the meantime. Others complain that the weather is too hot and hang around putting the world to rights instead...

Putting the world to rights is an activity that can be extended to a larger group once lunchtime has been declared...

With the washing complete the railcars definitely looked much more presentable...

As and when time allowed, the class 108, which is currently hiding away in the shed, received some 'beautifying' treatment, some pictures of which can be found in the class 108 section below.

Since the previous report, we mostly continued the pattern of using the hybrid class 127/108 when we were asked to provide a 2-car unit and classes 104 + 109 when we were asked to provide a 4-car. That makes life much easier for the crews because it avoids the need to couple and uncouple units at the start and/or end of the day.

An exception to the above was when the Wickham class 109 paired up with the hybrid class 127/108 for the Saturday evening and Sunday trains of the Classic Transport event which took place during the weekend of 5-6 July. The following pictures show the evening train at Glyndyfrdwy...

We also played a part in the 1960s weekend which took place during the weekend of 2-3 August. The 4-car unit made up of classes 104+109 was used during the daytime on the Saturday with the hybrid class 127/108 taking over for the Saturday evening and Sunday services. The latter enabled the following "Three shades of green" picture to be taken at Corwen on the Sunday with the two BR green liveries on the railcar and the Tilling green livery on the vintage Crosville bus.

The unit was given a Fuel Point (FP) exam on 06/07/25. One of the jobs was to check, and top up if necessary, the oil in the gearboxes...

Another job was to check, and top up if necessary, the oil in the final drives. That one often involves playing the game of 'pass the dipstick' to allow an accomplice, who is blessed with the benefit of daylight, to provide a second opinion as to the level of the oil on the dipstick...

The following picture shows the indicator (aka Engine/Air & Axle) panel in the cab of 50528...

The left and right columns of lights show the driver which engines are running along the respective sides of the train from front to back (top to bottom) and the ones in the middle show the state of the forward/reverse mechanisms in the final drives.

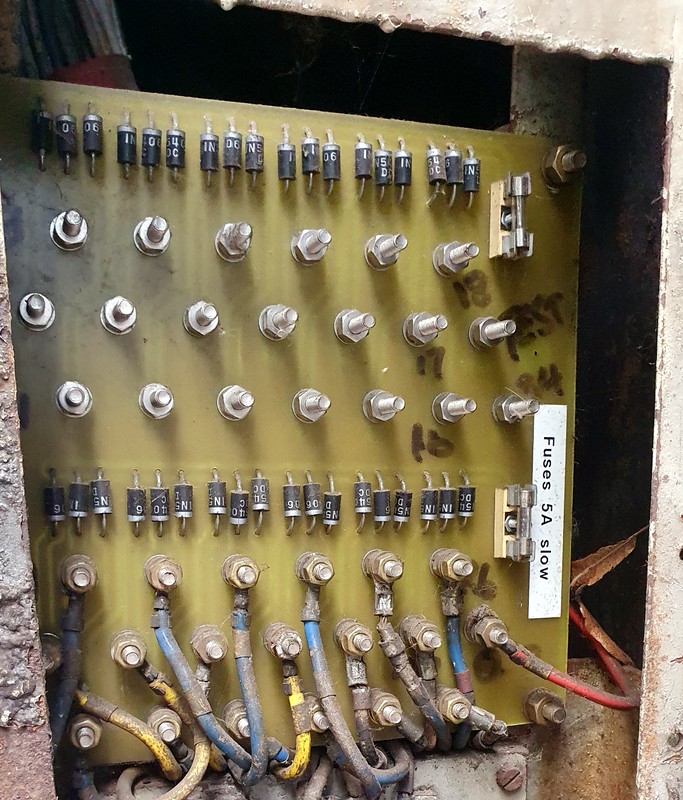

This particular panel had developed an intermittent fault whereby, every now and then, it would surprise the driver by turning off all of the lights. Crew members had discovered that pressing the combined Throttle/Driver's Safety Device control that is worked by the driver's left hand would usually result in them lighting up again - something that puzzled the 'electrical department' on the basis that the aforementioned control doesn't feature in the circuit (even though the gear controller/direction selector that is worked by the driver's right hand does). The fault was traced to a loose fuseholder on a diode panel that lives in the vicinity of the driver's left knee so the use of the throttle control was presumably causing sufficient vibration to remake the contact.

In the hope of fixing the fault in a reliable manner the whole panel was replaced and the faulty one became yet another "homework" project.

The growing conditions have presumably been just right because beading of various types has continued to spread around the vehicle...

The clever bit is knowing just where to plant the cuttings to further the process...

The following pictures show only a small fraction of the work that has taken place...

The sight of the almost-finished product prompted the owner to declare that it is now much too shiny to be allowed outside... :-)

Wickham Class 109 50416/56171>

If you've ever wondered what lives under the driver's desk of a heritage railcar, apart from several species and generations of heritage spider, here's an opportunity to have a nosey under the desk of the Wickham power car (51933)...

The reason for venturing in there was that the vacuum feed valve had taken to misbehaving.

There is a feed valve under every cab desk and its job is to present the required amount of vacuum to the driver's brake valve for use when the unit is being driven from that cab. That amount should be 21" Hg on a scale for which atmospheric pressure is 0" Hg and a perfect vacuum is approximately 30" Hg. Alternatively, when expressed as pounds per square inch (psi) atmospheric pressure and 21" vacuum are approximately 15 psi and 4.5 psi respectively.

If a feed valve develops behaviour that is either erratic or inconsistent with that of its counterparts in other cabs it can become difficult or impossible for the driver to fully release the brakes, as had been the case prior to this investigation.

The errant feed valve was extracted, taken to the workshop and stripped down...

The tension of the spring is adjustable and used to set the vacuum level to 21" Hg when the valve is installed.

In this case the cause of the fault was traced to a split in a diaphragm that is meant to be airtight. It looks as though it had part of a finger stuck in it too... :-)

The diaphragm was replaced and the feed valve reinstalled and setup so hopefully it will now behave. Drivers are already monitoring the behaviour of the one in the cab of the trailer car which works well for most of the time but then has its moments that can catch out the unwary.

Returning to the depot at the close of play one day, a driver discovered that it was impossible to close one of the sliding windows (or sliding lights to use the posh name). When the problem was investigated during a work

meeting it took some dealing with and included an outing for the impact screwdriver. It turned out that a plastic slider had been fitted incorrectly and its screws had come loose and jammed up the whole thing. It went back together assembled

correctly, with a bit of Loctite to hold the screws, and appears to work properly again.

A fan belt from one of the engines went missing in action...

...so the remaining belt was also removed and two new belts fitted...

On the Saturday of the Classic Transport event, the 4-car class 104+109 went back to Pentrefelin Depot after completing the daytime service and the Wickham class 109 was then promptly split from the class 104 and coupled to the hybrid class 127/108 set in readiness for the evening service. However, during the coupling operation, it was discovered that the air hose palm couplings wouldn't seal and a rapid change of air hose ensued followed by an equally-rapid change of clothing for one of the people carrying out the work who had to be transformed into a driver prior to setting off to Llangollen Station with the Empty Coaching Stock (ECS). A definite case of "Phew!"

Two ceiling panels in the front section of 56223 were tidied up because the paint had flaked back to the hardboard. The bare bits were given a dose of water-based primer, which dried in no time at all, and then the whole lot was given a coat of white gloss...

It's surely got to be worth paying the first class supplement just to be able to look at oneself in the ceiling?...

Some further investigations were carried out to try to find out why the class 127 power car loses its air pressure quite quickly whenever the engines are stopped during the layovers at each end of the line. To begin with the non-return valves associated with the two compressors were located, removed and stripped down...

One of the valves was quite badly worn and the other had a spring that wasn't actually doing anything, so "here's one we made earlier" provided one replacement and a kit of parts produced another. The rest of the vehicle pipework was then checked and this compressor delivery hose was found to be long past its use-by date, with leaks all over it...

The hose was replaced and the unit is now better at holding its air but it still has some catching up to do compared with the other units.

Restoration of the trailer car continued with the fitting of the missing beading that fits above the luggage rack. The luggage rack itself was then fitted after putting up a bit of a fight.

The flat ceiling at the back of the vehicle was completely removed so that work could concentrate on the frame which was bowed. It was levelled by cutting, and fixing, sloped lengths of timbers to the bowed frame. Once that had been completed, the panels and the light fitting were refitted.

Some more wall panels were drilled and fitted to the driver's side of the rear compartment.

The following pictures show the ceiling looking much better after refitting...

... and the securing screws for the bars being tightened after fitting the luggage rack...

Thanks to Allen Chatwood, John Joyce, Andy Lowe, Mike Martin, Graham Parkin, Martin Plumb and Neil Williams for supplying the pictures that were used in this edition.