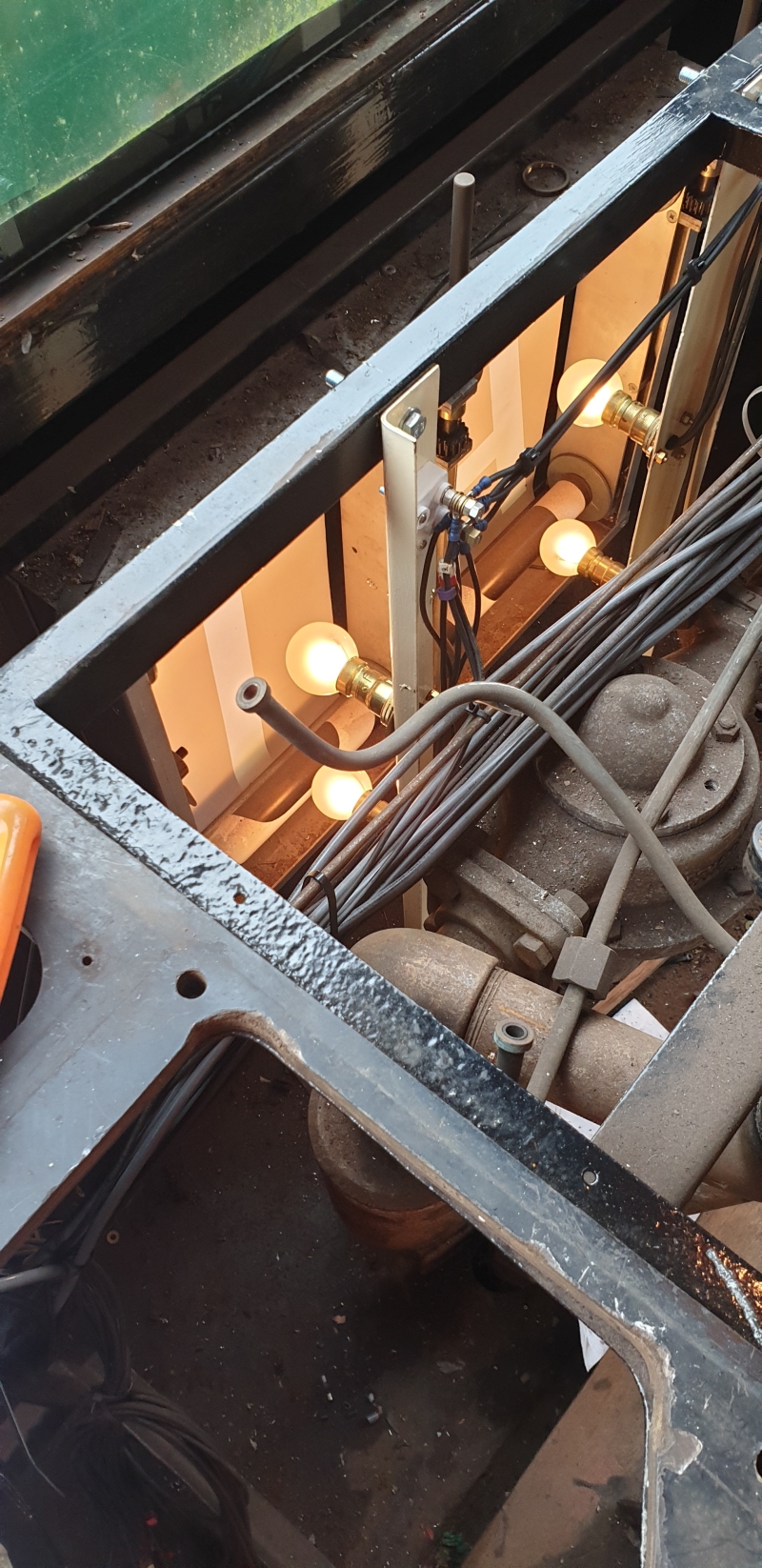

Over at the Midland various electrical jobs have been undertaken on the Gloucester. All of the 10mm cables in the cab have been crimped and terminated. The route indicator light support brackets have had grommets fitted ready for the wires. The saloon lights have also been connected up, all that is left for them is the half switch installing so that all of them can be used.

The route indicator light wiring was completed later in the week, and these can now be turned on. The drivers key circuitry was also tested and proved to be working! Time was also found to screw on some wooden batons to support the cab roof insulation.

Inside the 108, a morning was spent fitting refurbished sliding lights, but a problem was encounterd with the old sliding light on one side not butting up flush with the new sliding light. The old one is starting to fall apart so this has also gone for refurbishment.

The 105 team spent some time inside the 127, adding insulation to the areas where the bodywork has been completed. After doing nearly the whole of the 105, they have this down to a fine art! A team also worked inside the 127 to line up the interla window frames, and drill securing holes into the new body panel. Once this has done they were then secured to the body.

The next passenger door, and the internal wall panels on the next section of bodywork to be tackled were then dismantled. The guards opening door has also been dismantled to have attention to the lower section which is corroded.

The newly refurbished destination box for 51933 has been finished off, with the addition of the remaining parts, the blind now rolls nicely! Work has also taken place to dismantle the timber frame around the centre windscreen. There is some cutting to do before the job can be finished.

Inside the 105 more insulation has been installed, and the remaining timber pieces fitted in. A few more screws have been added to the wall panel fitted last time to stop it from bowing. A new piece has then been cut and fitted between the two windows. The inside of the first class is really starting to take shape quickly!

Some of the electrical items for the Gloucester trailer car have been cleaned up with liberal use of a wire brush, and prepared for painting. The dynamo regulator cupboard has also been cleaned up, lots of scrapping followed by a wire brush wheel and an angle grinder.

More air system jobs were also done on the 104 M exam. Re-fitting the non-return valves has proved to be difficult, with one of the threads on the compression nuts being damaged. A new compression ring will have to be sourced at a later date.

Work has continued on the 104 M exam, with the end getting to something like in sight. These jobs focused around the air system, including the unloader valves, control air filters, and non-return valves. The safety valves have also been removed to be stripped down, and tested on an air supply which is a bit more easily controlled.

The brakgear was generously lubricated, and the tyre thickness, plus flange height and thickness was recorded.

Part of the newly fitted steelwork in 51618 was given a good coat of chassis black, and the next section was stripped down ready for attention to more corrosion.

Various bits for 56097 have been delivered back ready for onward shipment to Butterley, plus the freed up tension roller for the destination blind in 51933.