Saturday 15 February marked the start of our running season with the class 108 initially being allocated the six 'Timetable A' duties between then and the end of the month. The following pictures show it leaving Llangollen and passing Pentrefelin with the 10.00 to Corwen on a gloomy Sunday 16 February...

When the class 108 developed a minor air leak on its no. 2 compressor, it was decided to sideline it for repair and let the class 127 play out for a couple of days instead. Unfortunately, on its first day out on Wednesday 19 February, the class 127 became rather lethargic from Glyndyfrdwy onwards with the last train back from Corwen. The journey from Glyndyfrdwy to Llangollen wasn't particularly problematic because it is mostly downhill but the subsequent climb up to the depot at Pentrefelin caused the crew some nail-biting moments. It turned out that the unit was operating on 50% power and with just one driven axle due to an oil leak associated with the no. 1 torque converter.

We are pleased to report that the air and oil leaks on classes 108 and 127 respectively were both repaired on Thursday 20 February and the units were soon given a clean bill of health again.

A major milestone was reached when the sliding door at the back of the unit was finally made to work properly because its curved track had caused all kinds of difficulties in getting all of the supporting cast (timber framework, runners, ceiling and wall panels etc.) in just the right place. The following pictures show the fitting of the bolts that secure the door to the track...

...some final adjustments...

...and the completed product viewed from inside and outside the vehicle...

Once the door had been seen to be up-and-running, attention turned to the installation of the panels on the back wall...

The ceiling panel was also re-installed albeit after the above photograph was taken.

The repairs to the secondman's door, which had been found to be in poor condition, were concluded and it was given a coat of primer...

A start was made on fitting the electrical equipment to the refurbished battery boxes...

Also on the electrical front, the wiring to the engine and air & axle indicator lights in the cab was completed...

Class 108 51933/54504

An air leak on the no. 2 compressor was fixed by replacing a gasket...

The compressor sits on top of the engine and can be accessed via one of the trap doors in the passenger saloon as shown in the following picture...

The project to make improvements to the braking system on the no. 1 bogie of the power car (50416) - which forms part of, and is now roughly two-thirds of the way through, a longer-term project to 'fettle' the braking system on the entire unit - progressed with various activities including the cleaning of various items of brake gear...

...modifying brake block carriers in order to restrict the sideways movement of the blocks and prevent them from taking excursions round the sides of the wheels...

... and, it seems, pulling rabbits out of hats...

Seriously, the above picture shows the inside of a vacuum brake cylinder being cleaned.

The culmination of all of the above saw the testing of the vacuum cylinder using the neighbouring class 104 to provide the vacuum (or exhaust the air depending on your point of view)...

...and a collection of brake blocks to provide the necessary load on the piston rod...

The time then arrived to make a start on refitting the brake gear. The vacuum cylinder was fitted with the aid of our specially-modified trolley jack together with some grunting and groaning...

...and the other components were re-installed with grunting and groaning alone...

On the outside of the unit, the project that had begun with "I bet this unit will look a lot better if we give it a coat of varnish" became more involved than anticipated as is often the case. The need to first of all ensure that the bodywork was in sound condition resulted in the need to dig out, and replace, the filler over the rivets...

...and there were occasions when the person doing said work was astonished by the size of some of the loose bits of filler that fell out...

To enable you to judge the size, the thumb in the above picture is a full-scale one (scale=1:1)!

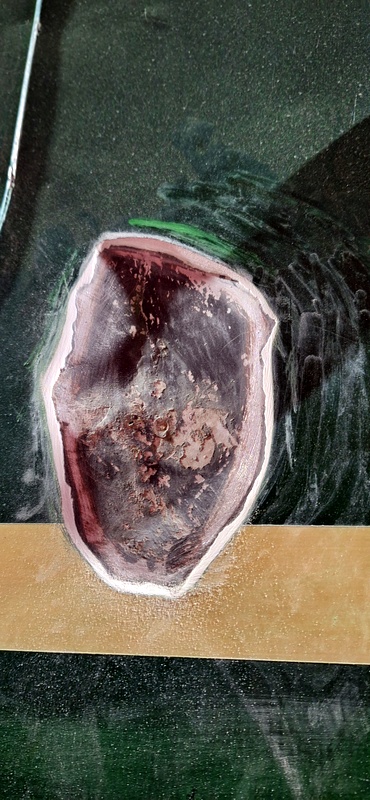

This is what the bodyside looked like after the sizeable chunk of filler had been disturbed...

The brown colour is assumed to be a hangover from the livery that it sported during its time at the Chasewater Railway back in the 1980s and early 1990s.

With the filling and sanding completed, the bodyside could be scuffed and then varnished...

The initial thought turned out to be correct because the varnish has made a considerable improvement to the appearance. The following pictures show the varnished power car (50416) and the trailer car (56171) scuffed in readiness for the same treatment...

Another significant improvement was made with the application of some buffer beam red...

As mentioned in 'Out and About' above, a loss of oil from the no. 1 torque converter resulted in the unit limping home (with 50% power and only one driven axle) from Glyndyfrdwy at the end of its first day out this year (Wednesday 19 February). The cause of the problem was identified and rectified the next day and a short test run along the 'back road' on Saturday 22nd proved that all was well again.

While two members of the team spent a day cutting and drilling many different beads for the secondman's side of the rear compartment, all of which were then taken away as "homework" for painting or staining/varnishing as appropriate, their leader installed the front panel for the water tank - something that required some 'tweaking' to the previously-installed framework and the need to deal with a snapped screw before everything eventually fell (?) into place...

Thanks to Allen Chatwood, John Joyce, Andy Lowe, Mike Martin and Graham Parkin for supplying the pictures that were used in this edition.