The first 2025 working meetings at Llangollen took place during the weekend of 4/5 January and the intrepid volunteers who turned up for work on Sunday 5th were greeted with these wintry scenes following some overnight snowfall...

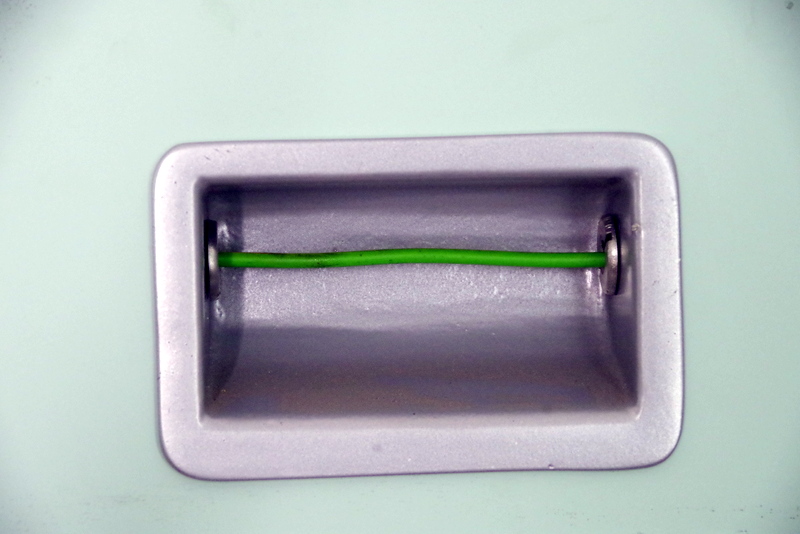

The passenger communication (passcom) cord was installed over much of the length of the secondman's side of the vehicle, the exception being the section nearest the back which cannot be processed until the toilet wall has been completed. The passcom presents itself at a number of locations in housings like this one...

...so that the chain can be pulled by a passenger in the event of an emergency. The linkage then operates a valve in the vacuum brake pipe as a way of applying the brakes and alerting the crew.

The chain was clamped at the end nearest the front of the vehicle...

...and then threaded along the vehicle using some electrical cable as a draw wire...

To add to the fun there is one place where it has to undergo a change of height via an 'S' bend...

Work continued with the secondman's door which was found to be in poor condition. As well as a number of repairs that needed to be carried out on the outside, the wooden frame is quite weak in places and is having to be reinforced with some custom-made metalwork.

In the previous edition it was reported that work was progressing with the battery boxes and the corridor connection, albeit without any supporting pictures. Here are the pictures...

Hybrid Class 127/108 (51618/56223)

Towards the end of the last running season the 51618 no. 2 engine developed an oil leak from a joint on one of the pipes that lead to the oil filters (the location is shown by the red circle in the following picture) so last Saturday it was decided that the time had come to effect a repair.

Jobs often turn out to be more difficult on the class 127, due to the amount of gubbins that is crammed into the underfloor space, and this one was no exception because it was necessary to remove a heater, an exhaust bracket and an engine electrical conduit in order to gain access to "the scene of the crime"...

Having done that the required component (namely the housing that supports the oil filters and the pipes that connect them to the engine) could be extracted...

...and taken for an appointment with the parts washer where it was made to look "good as new" (well almost)...

After some new 'O' rings had been fitted to cure the oil leak it was a case of "assembly is the reverse of disassembly" but it was perhaps as well that we carried out a test before reinstalling the heater etc. because it turned out that we had used incorrect 'O' rings and the oil was still able to get past them. We were, therefore, able to file the dismantling/reassembly process that had already taken place under 'rehearsal' before setting about tackling it for real. After fitting the correct 'O' rings all was well- the oil leak was cured and we even tested the heater to make sure that it had not been upset in any way...

The project to make improvements to the braking system progressed with the removal of the vacuum brake cylinder and all of the associated brake gear from the no. 1 bogie of the power car (50416)...

A start was then made on cleaning up those items...

Back in the spring of 2023 some additional grab handles were fitted to the doors of the guard's compartment on the secondman's side of 50416 in order to make it easier and safer for guards to climb up and down from/to track level (see the April 2023 news page). The same modification has now been carried out on the driver's side, for which the following pictures show the 'before', 'part way through' and 'after' phases of the job...

All that remains to be done is to give them a finishing touch of paint and then we can perhaps see about auditioning for a guard for the publicity shot :-)

Thanks to John Joyce, Andy Lowe and Craig Robertson for supplying the pictures that were used in this edition.