Sadly it is not all good news this time because our Gloucester Class 100 unit at the Midland Railway, Butterley suffered three broken windows during an attack by vandals on Monday 23 January which also resulted in damage to various other items at the site.

Needless to say this mindless vandalism will result in time, effort and funds being diverted from more worthwhile things.

Information about work that has been carried out on some of the railcars at Llangollen since the previous report can be found below.

Most of the remaining jobs on 50454's 'C' exam were tackled including checks on brakes, doors, earth leakage, the remainder of the belts, fire detectors and buffer heights. The sliding ventilators (aka windows) were subjected to more 'fettling' and eventually all made to work in a reasonable manner, the definition of 'reasonable' being determined by the need to prevent this particular job from turning into a career!

One of the drawbacks of restoring and maintaining vehicles that are 60+ years old, but were not designed with such a life expectancy in mind, is that there are surprises 'round every corner' and jobs that start out as simple often become much more difficult and time-consuming than anticipated. One example was the need to secure a loose striker plate on the driver's door of 50454 which, because of the state of the door pillar and its woodwork, required a great deal of persistence with welder, grinder, drill and a set of taps in order to secure the striker plate and make the door operate properly again. The woodwork will require a bit more thought.

The long-standing issue of a leaking final drive seal on 50454 was investigated. That involved removing the seal plates from around the axle...

...in order to expose the seal and its inscription...

It could not be assumed that the seal in place was the correct size for the axle so measurements were taken...

The outcome was that we do not have replacement seals of the required size so we will need to source some.

The other side of the gangway faceplate was cleaned and painted as were various fittings for it.

Some more wall panels were cut, drilled and fitted and one of the aluminium window surrounds was fitted.

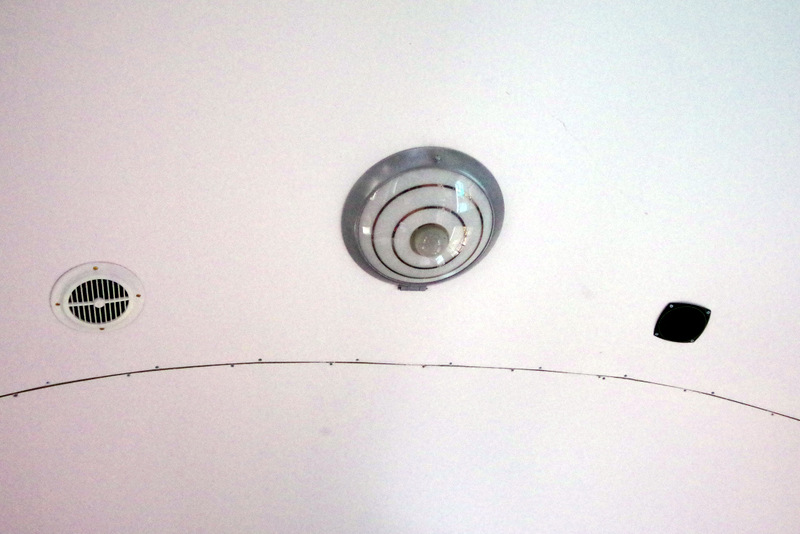

The remaining ventilator covers that rather craftily hide the speakers for the public address system in the ceiling were fitted...

Further work was carried out on the electrical connections at the rear of the vehicle. First of all the wires were soldered to one of the jumper sockets for the secondman's side of the vehicle...

...and then the wires were fed through the conduit leading to the other side. That involved negotiating a corner with a tight fit so it required some persuasion from a team of three people...

There are no prizes for spotting that only two people can be seen in the above picture! Perhaps the third one was temporarily excused to take the picture?

The reassembled brake gear on the no. 2 bogie of 56171 was tested using 50454 to generate the vacuum and we were pleased to confirm that everything worked correctly.

A door that suffered a droplight failure some time ago was taken off, dismantled, given a new droplight, and refitted.

The Cravens restoration team very kindly used some of its new new light green panelling to produce a sample door panel for the class 127. That has now been fitted to one of the doors and it looks very good...

Thanks to Allen Chatwood, Evan Green-Hughes, John Joyce, Mike Martin and Graham Parkin for supplying the pictures.

Our first meeting of the new year took place at Llangollen on Sunday 8 January. The rain in the morning turned out to be much heavier, and more prolonged, than the forecast had led us to expect so we were filled with a desire to find jobs that could be carried out in the dry. Fortunately there were various things that could be done inside the shed and the continuation of the 'C' exam on the class 104 vehicle 50454 enabled us to 'cherry pick' the jobs that could be done inside the vehicle, at least until lunchtime when the weather improved. Further information about the work that was carried out can be found below.

The 'C' exam on 50454 progressed with a number of jobs that could be carried out inside while the rain lashed down outside - at least until lunchtime after which the rain had finally stopped and we were able to tackle some outside jobs as well.

The driver's brake valve was dismantled, lubricated and reassembled...

The picture was taken after the top cover of the valve (i.e. the black item with the inscriptions Off, Lap, On) had been removed and the components separated. The fixed part of the valve is nearest the camera and the rotating part, which sits on top of it, had been removed, turned upside down, and placed on the desk between the fixed part and the gear controller.

As can be seen, the fixed part has two openings or ports, both of which are connected to pipes that run the full length of the train. One of them leads to the brake cylinders and is used to work the brakes, and the other leads to the exhausters (the devices that create the vacuum) and to reservoirs that are charged with a high vacuum. Under the driver's control the valve is used to perform one of three different functions: On: Admit air into the brake pipe from the cab in order to apply the brakes (thereby creating the sound that is heard by the passengers sitting behind the driver), Off: Connect the two ports together in order to create a vacuum in the brake pipe to release the brakes and then maintain the required vacuum during normal running, Lap: Close off both ports in order to maintain a required level of braking. The lap position is also used to isolate the valve so that the train can be driven from elsewhere.

Other inside jobs that were completed included the lighting, emergency equipment, and trap door checks.

The sliding ventilators (the posh name for what most people might describe as the small sliding windows above the main windows) were given a 'dose of looking at' and, as a result, most of them can now be operated without the need to first of all build up one's strength by consuming shredded wheat* and/or spinach. By the close of play, however, one or two of them were still putting up a bit of a fight so they will be dealt with at the next meeting.

* Other breakfast cereals are available!

Once the rain had stopped the spring hangers could be lubricated...

... and most of the electrical jobs could be carried out. That included a health check of the batteries using a tester that applies an electrical load (aka a miniature electric fire) to ensure that they perform correctly under load ...

The gangway faceplate assembly was cleaned and painted...

Class 108 (51933/54504)

Two covers for the EP boxes (i.e. the boxes that contain the electro-pneumatic valves) on the power car (51933) were cleaned up and primed. These have the big knurled chrome knob and will be used to replace the ones with wingnuts that seem to take forever to unfasten and fasten.

Class 127 vehicle no. 51618 (undergoing bodywork repairs at Llangollen)

Some packets of insulation were constructed and fitted to the recently-repaired sections of bodywork. The insulation is encased in plastic bags to keep it dry in the event of water ingress.

Thanks to John Joyce, Mike Martin and Martin Plumb for supplying the pictures.