The feed valve in 50416 was swapped out for an overhauled one. This has solved the issues with vacuum, one our newer members discovered that only 7 bolts hold the valve in, there are a lot of pipes to remove to free it from the desk area.

The guards door in the same vehicle on the secondmands side has been dragging on the floor. An angle grinder fitted with wood grinding discs was used to sort out the problem, before the door was rehung. The drivers side inward opening door had some attention to the striking plate, and more minor attention with the grinder. Following on from this both vehicles had a good interior clean ready for the intense running coming up.

Some electrical items for the Gloucester have been painted, it seems like a never ending job but will all be worth it when they are refitted to the vehicles.

In the 127 two windows were removed and refitted with new rubber, they went in a lot easier than the last time we tried with different rubber, and hopefully all of the windows can have the same treatment. A dose of sanding and filling also took place.

The 104 drivers door was also finished off.

A busy week on various projects around the depot, as well as running a midweek service at Llangollen.

A few minor faults have been attended to on the 104, a fussy BIS switch was put in order so it now works first time, and an unloader valve was also adjusted to work better in service. What started as a simple task of reattaching a drivers arm rest turned into making a whole new door panel, but this has also now been sorted. A slight leak in the guards setter was also cured with some new washers.

After two weeks of running the unit was given an external wash, and is pictured below waiting to take the first train to Carrog.

Major work to restore the bodywork on 51618 has continued, with a large part of the body-side having been sanded down ready for painting, the rear most passenger door has also been rehung on the vehicle, and the wooden door jams fitted. The window surrounds and trim have also been refitted.

The Wickham was shunted at the end of the week ready to take up duties today, during the weekend a sticking door was dealt with, and now fits like a glove again.

The "new" 108 had it's annual "A" exam, and celebrates just over a year of being with us at Llangollen. One fan drive belt was adjusted, which involved fitting a new thread on the adjuster as it was stripped. Bolts in one propshaft have also been swapped to the BSF standard to match the other sets. A minor adjustment to the brakes on one bogie, and a wash with the gutter blaster MK1 completed things.

Inside the Cravens the team have continued with the wall paneling in the 1st class, on the secondmans side. All that is left to do is the section behind the luggage rack.

Over at the Midland the exam on the 141 has been finished off, with the hydrostatic filters being replaced, and the topping up of the oil levels. The 108 has also had the oils topped up ready for service.

In the Gloucester trailer the refitting of timbers has progressed above the luggage rack frames. Framework for the can insulation has also been fitted. Cleaning of the luggage rack bolt threads continued, with most of the drivers side now done. The door lock taken off last time has been refurbished and refitted.

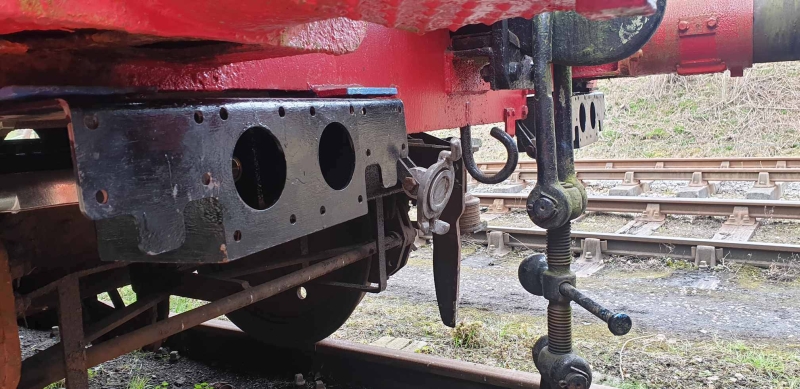

The studs for the front jumper box have been welded into place, and the boxes fitted. All of the black castings have been fitted, the white ones will follow once the gloss has dried. The conduit taking the wires through to the cab floor have been fettled to allow good access when the wires are run. A little more conduit is needed though before this can take place.

It's been a busy week at Llangollen with the 104 out on all of mid week days apart from Monday. The unit is pictured below returning to the depot for a well earned rest on Friday afternoon.

One or two niggles came to light, including a faulty engine start button for the no.1 enginge on 50528. This was replaced with a fresh one from stores, swiftly followed by the old one being stripped down, cleaned and reassmbled, ready to be tested and then returned to stores for future use. An EP valve that had also been swapped out was stripped down, and replacement parts fitted and is back on the stores shelf.

Over at Butterly the rain and adverse weather got in the way slightly of the plans, but the secondman side front jumper box was made up to a point where it could be mounted ready for wiring. The jumpers that were still in primer have had the first coat of gloss applied. The secondmans side of the desk has been refitted, and the saloon lighting switch installed.

As work is turning the first class saloon this area has been cleared of all things electrical, and the half lighting circuit temporaily wired out to allow all the vehicle lights to be swithced on.