Many people have admired and have ridden in the award-winning Wickham unit but few realise the amount of work that was involved in bringing this set back from the dead.

Driving Motor Brake E50416 was in a poor state and contaminated with blue asbestos when we first saw it in store at the Chasewater Railway, these pictures chronicle its rescue and subsequent refurbishment.

When we purchased 50416 it had been converted for departmental use. Some of the doors had been plated up while others were in a non-standard position. The general structure and condition was very poor as this photo, taken shortly after it arrived at the Midland Railway for restoration, shows.

Inside there was nothing left of the 'art-deco' interior and crude passenger accommodation had been added at the Chasewater Railway.

The first job was to arrange for the deadly blue asbestos to be removed from the interior, which was done by specialist contractor. This left the interior a stripped out and bare shell. This picture shows what would later become the guard’s van but which at that time had had a non original small window fitted.

Work commenced in this area to return the windows and the body sides to their original condition. During this operation it was discovered that there was severe corrosion to the roof sheets.

Where doors were missing brand new ones were manufactured and fitted in the original positions. This transformed the appearance of the coach even at this early stage.

After several months of hard work the body had been taken back to bare metal. The rear end had been thoroughly repaired and new doors made. The gutters were removed and a section let in to the roof all the way round the coach. New gutters had to be made and fitted lower down in their original position.

The interior was painted out once the modifications to original were complete, this is the same area as shown in the earlier photo and would eventually become the small rear passenger compartment and guard's van.

With the sides painted out work started on the floor. The original wood was removed so that the metal could be checked and painted. This was dusty and dirty work.

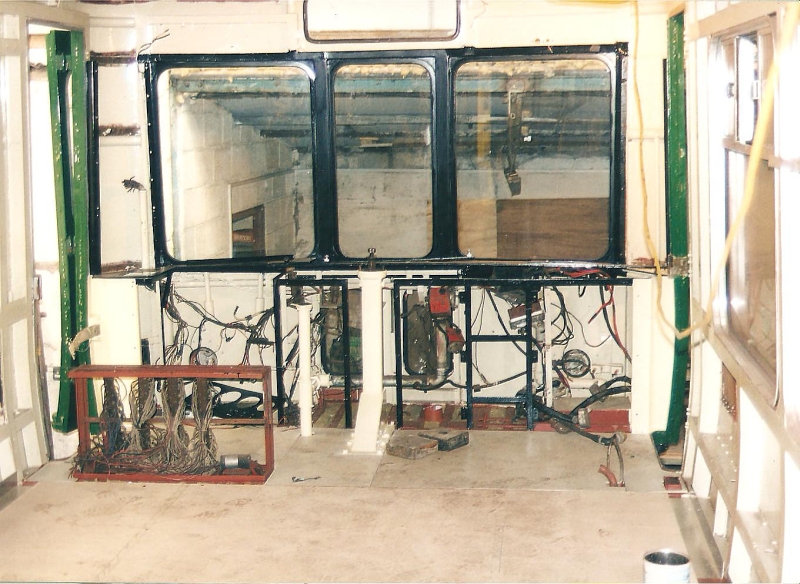

Work then began on fitting out the interior, starting with the driver’s cab. As can be seen a complete rewire was required but as much as possible of the original structure was used in the rebuild.

While this was going on the vehicle was lifted off its bogies, which were then stripped down to their individual components. These were then checked over and repaired as necessary before being repainted and reunited.

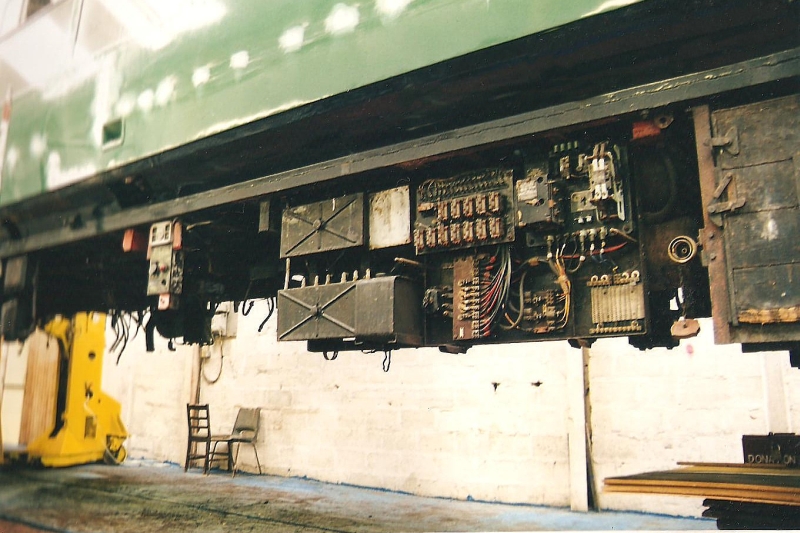

Components removed included both engines and both gearboxes, as well as fuel tanks, generators, radiators, fans and exhausters.

The pile of components requiring refurbishment at one period occupied the whole of a storage coach and occupied many people over many years before they were all restored.

Once the floor was back in a start was made on fabricating the art deco partitions. These were scaled from measurements of the vehicle, drawings of the glasswork and photos taken of the original in the works. A jig was used to make sure that they were all the same size.

Insulation was installed in the sides while the partitions were blocked out with woodwork.

A specialist contractor was engaged to make the interior wall cladding. This is a wood finish bonded onto aluminium and was a particular feature of the original Wickham design. In this shot the new panels are being fitted, while the wooden ceiling is being painted.

Inside the new doors were embellished with new woodwork to the original pattern. This was hand made, requiring many coats of varnish before a satisfactory finish was obtained.

Following completion of the restoration of all the mechanical components a mass working day was held during which engines, gearboxes and radiators were refitted over the course of 12 hours. One of the Leyland engines is seen being winched into position using one of the Wickham’s on-board winches.

All the wiring had to be renewed, with some of the new cable seen in this picture of the terminal box which is behind the driver’s seat in the cab. The components for this job cost more than £3,000 per car.

The centre trays on which the lights sit had long ago disappeared and had to be made again from scratch. These were eventually made from fibre glass with the colour moulded in permanently. The same technique was used for the cab roofs. All these components were originally hand-beaten from aluminium. The luggage racks were also made new and involved hundreds of components.

Another shot of the van area of 50416 following the installation of the guard's van partition and the emergency cupboard.

Following five years of hard work and almost £200,000 (much of which came from the Heritage Lottery Fund) the finished item carried its first passengers in Spring 2004. On this run were some of the craftsmen who had built the unit in 1957 and most of those involved in its rebirth more than 40 years later.

In service and doing what its designers intended 50416 is the only Wickham power car left in the world and is a unique example of both its manufacturer and the method of construction. It has now completed more years in heritage service than it ever did on the main line and is now close to 60 years old.